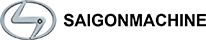

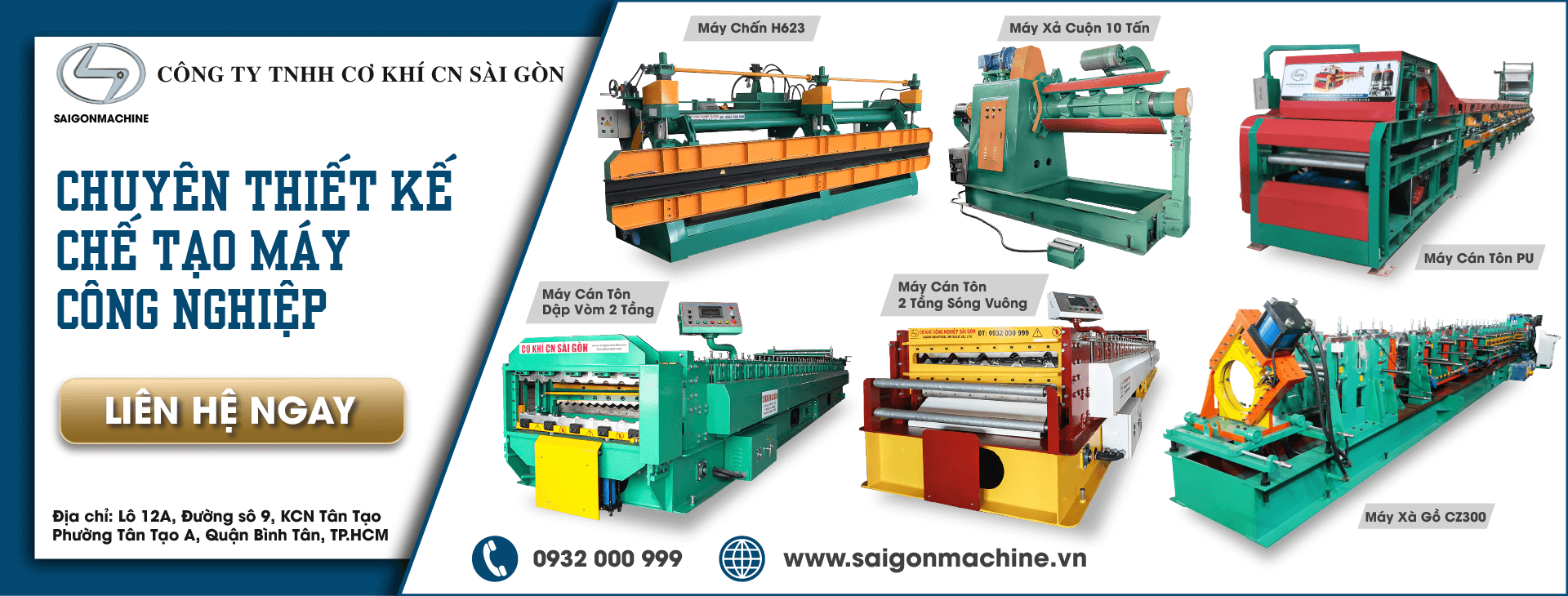

SAIGON INDUSTRIAL METALLIC CO., LTD|SAIGON MACHINE – SGM

Saigon Industrial Metallic Co.,Ltd|Saigon Machine – SGM is one of the leading enterprises specializing in designing and manufacturing industrial machines for the steel industry in VietNam.

As the first Vietnamese company to invest in Copra software from DataM – Germany,...

PRODUCT BY SAIGONMACHINE

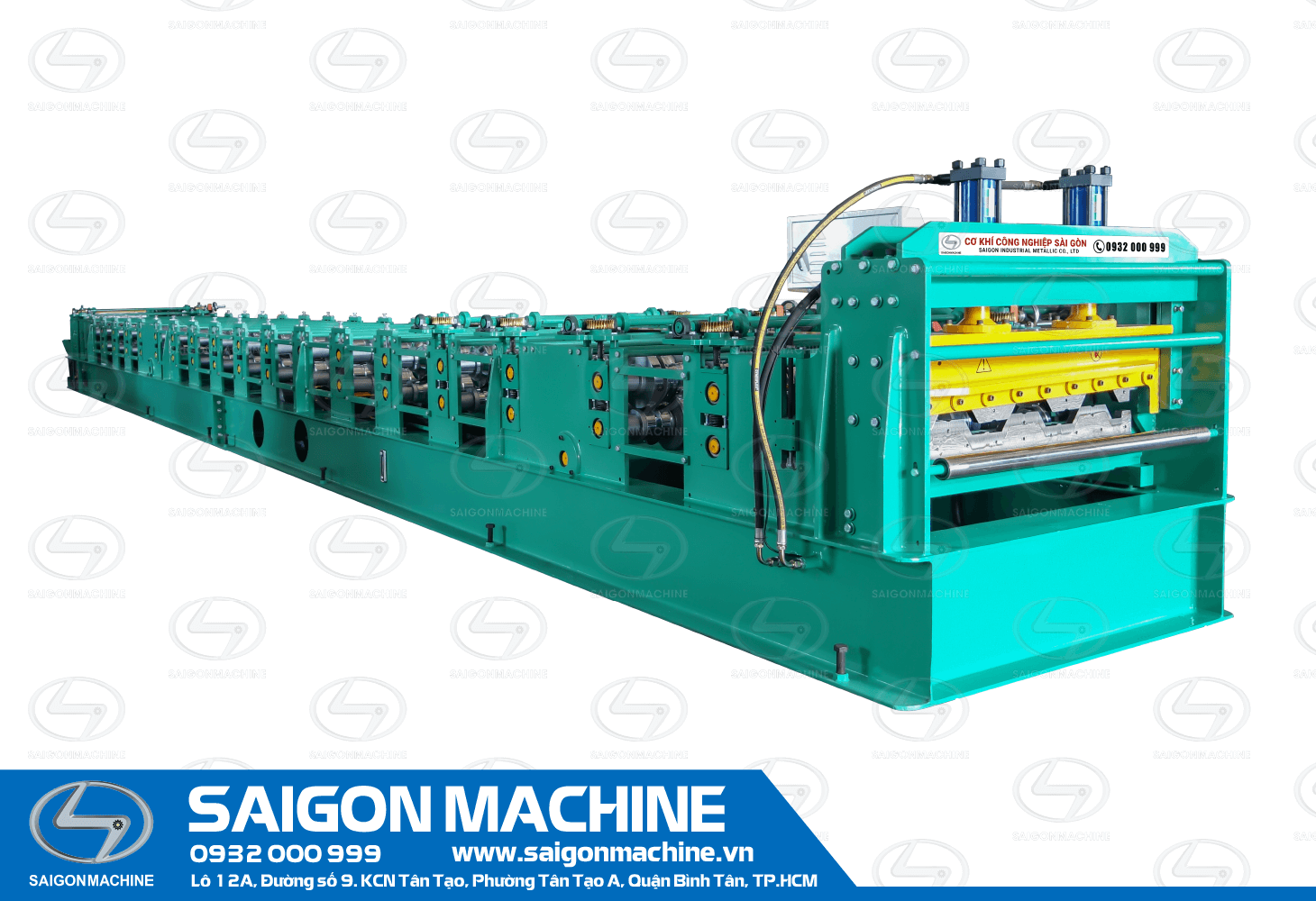

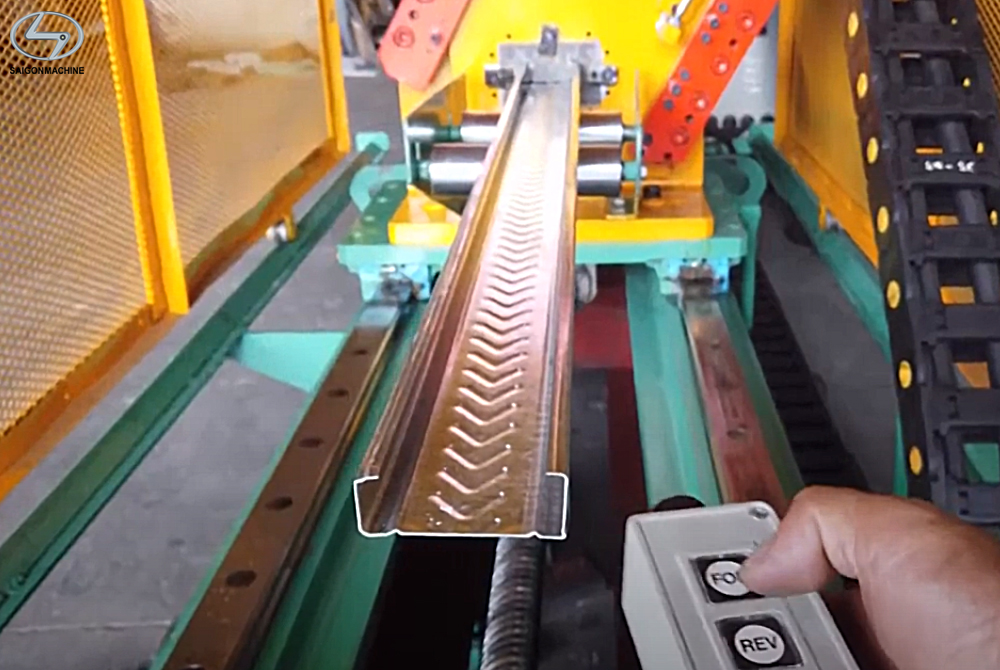

Floor decking roll forming machine - H45 | H50 | H71

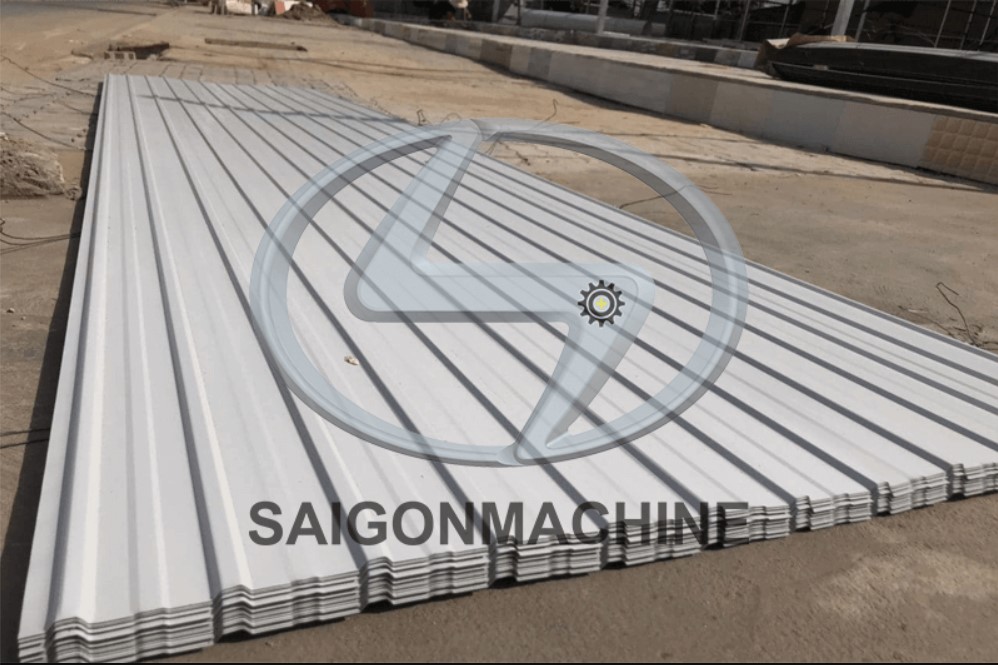

Floor decking roll forming machine - H45 | H50 | H71, manufactured into Floor Decking, is understood as a corrugated iron floor plate linked on a steel structural beam system by welded nails. Floor Decking is manufactured at the factory with high technical requirements, this type of floor has the effect of replacing floor formwork without the need for a support tree. Combined with bearing forces with reinforced concrete floors, it helps to speed up the construction progress.

Scope: Construction industry and building structure.

Without using formwork, construction time is 3 times faster, saving 30% of concrete. Quick completion and installation of accessories and subfloor components right after pouring concrete. Floor decking roll forming machine - H45 | H50 | H71 is a product that receives many orders from domestic and foreign customers

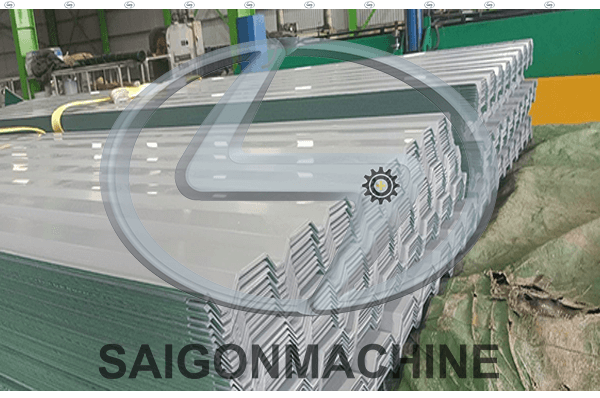

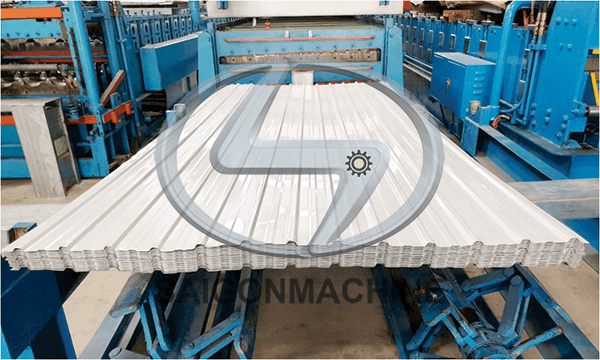

Single layer - Roll forming machine - Kliplok | Kliplock roof - Useful 970

Single layer - Roll forming machine - Kliplok | Kliplock roof - Useful 970, a new development in the screwless roofing industry, corrugated iron has the deepest jaws, so it increases grip on the clamp belt, Australian-style side corrugated iron structure so it doesn't collapse when roofing and increases grip At the side corrugated iron, screws are fired on the clamping belt to increase the life of the roofing sheet. Satisfy projects with large roof lengths with mobile corrugated iron rolling machines. Hydraulic machine control system combined with Inverter helps the machine operate smoothly, achieve productivity and save electricity.

Single layer - Roll forming machine - Kliplok | Kliplock roof - Civil - Useful 442

Single layer - Roll forming machine - Kliplok | Kliplock roof - Civil - Useful 442, a new development in the screwless roofing industry, the corrugated iron has the deepest jaws, so it increases the grip on the clamps, the Australian-style side corrugated iron structure prevents the corrugated iron from collapsing when roofing and increases the degree of strength. clinging at the side corrugated iron, screws are fired on the clamping belt to increase the life of the roofing sheet. Satisfy projects with large roof lengths with mobile corrugated iron rolling machines. Hydraulic machine control system combined with Inverter helps the machine operate smoothly, achieve productivity and save electricity.

Single layer - Roll forming machine - Lockseam | Seamlock roof

Single layer - Roll forming machine - Lockseam | Seamlock roof, with specially designed rolling mill and cutter die for excellent profile. Lockseam | Seamlock solution connected corrugated board - Seam corrugated iron panels with profiled corrugated iron, connecting thin edges are designed to meet all architectural requirements.

With a buckle design that bends, tapers and seals, allowing the screw to be concealed underneath the corrugated iron - an innovation that meets aesthetics, versatility and efficiency.

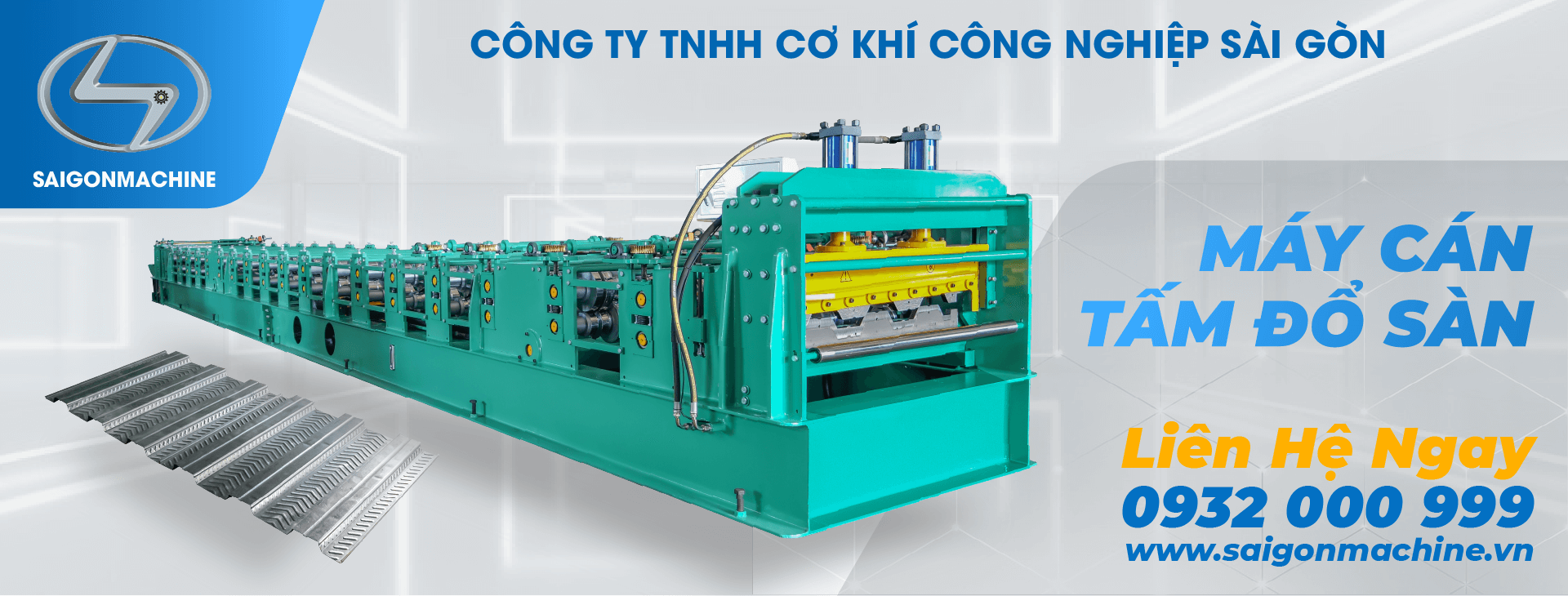

Floor decking roll forming machine - H76

Floor decking roll forming machine - H76, manufactured into Floor Decking, is understood as a corrugated iron floor plate linked on a steel structural beam system by welded nails. Floor Decking is manufactured at the factory with high technical requirements, this type of floor has the effect of replacing floor formwork without the need for a support tree. Combined with bearing forces with reinforced concrete floors, it helps to speed up the construction progress.

Scope: Construction industry and building structure.

Without using formwork, construction time is 3 times faster, saving 30% of concrete. Quick completion and installation of accessories and subfloor components right after pouring concrete. Floor decking roll forming machine - H76 is a product that receives many orders from domestic and foreign customers

Single layer - Roll forming machine - Kliplok | Kliplock roof - Useful 1000

Single layer - Roll forming machine - Kliplok | Kliplock roof - Useful 1000, a new development of the screwless roofing industry, the corrugated iron has the deepest jaws, so it increases the grip on the clamps, the Australian-style side corrugated iron structure prevents the corrugated iron from collapsing when roofing and increases the degree of strength. clinging at the side corrugated iron, screws are fired on the clamping belt to increase the life of the roofing sheet. Satisfy projects with large roof lengths with mobile corrugated iron rolling machines. Hydraulic machine control system combined with Inverter helps the machine operate smoothly, achieve productivity and save electricity.

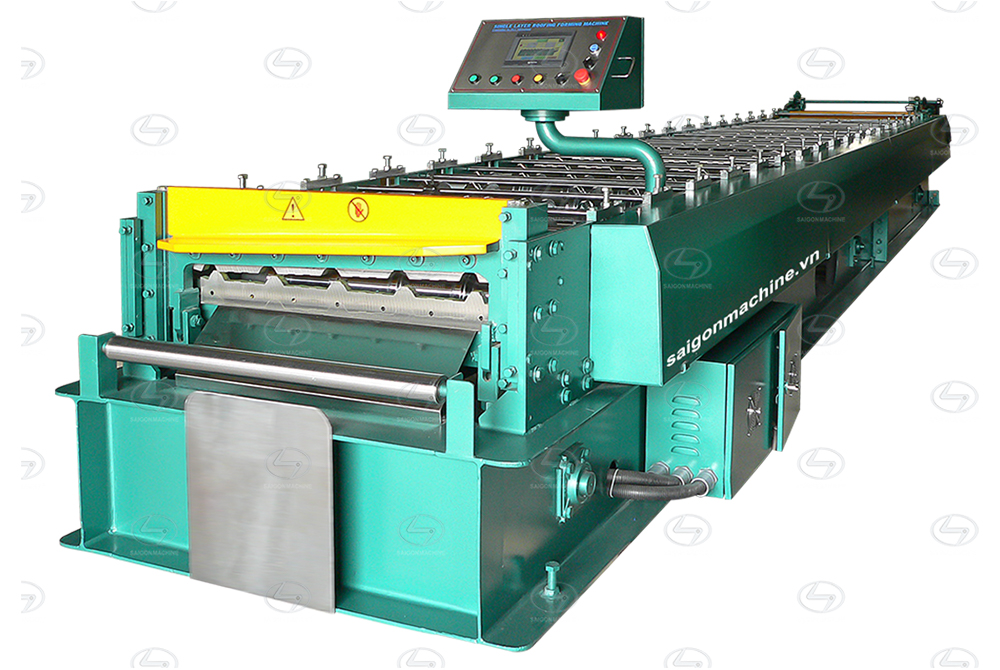

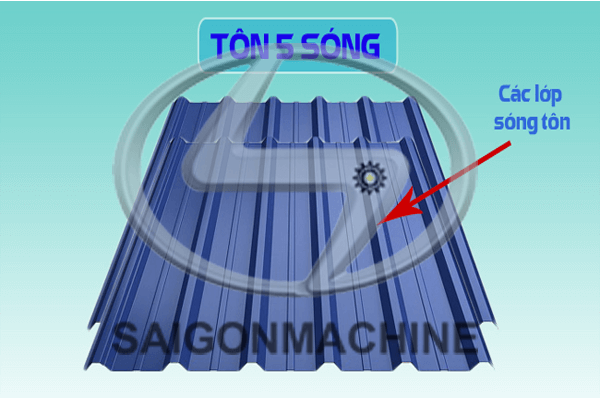

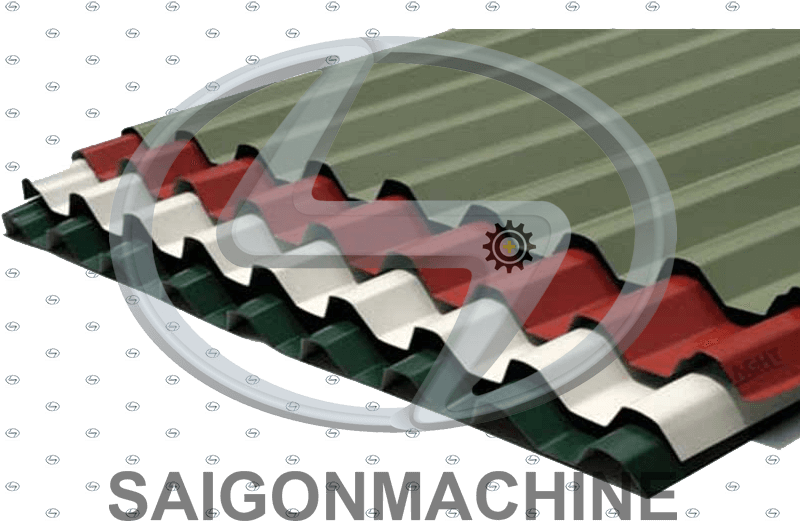

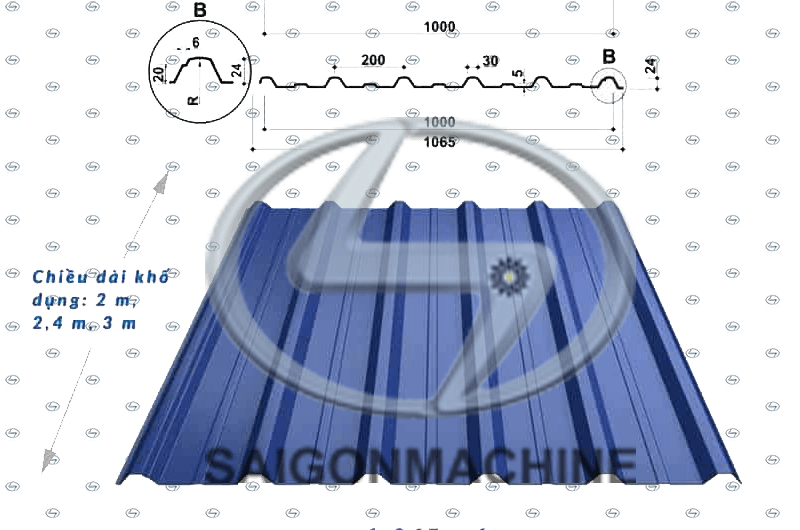

Single layer - Roll forming machine - Ribs roof trapezoidal

Single layer - Roll forming machine - Ribs roof trapezoidal, roll forming corrugated iron sheets with a variety of designs and types, especially Saigon Machine - SGM specializes in making all kinds of corrugated iron forming machines to accurately shape the profile required by customers. Can be set to run in batches of multiple sizes.

Single layer - Roll forming machine - Circulars corrugated

Single layer - Roll forming machine - Circular corrugated can roll and shape corrugated iron sheets with a variety of designs and types. Can be installed to run in batches or multiple sizes to save maximum cost for customers.

Single layer - Roll forming machine - Ribs roof plafonds

Single layer - Roll forming machine - Ribs roof plafonds, can roll and shape corrugated iron sheets with a variety of designs and types. Can be installed to run in batches or multiple sizes to save maximum cost for customers.

Single layer - Roll forming machine - Ribs roof trapezoidal - Indonesia

Single layer - Roll forming machine - Ribs roof trapezoidal - Indonesia, rolling and forming corrugated iron sheets with a variety of designs and types, specialized for use for 914mm corrugated iron - Useful 765 mm, especially Saigon Machine - SGM specializes in making corrugated iron sheets. type of corrugated iron forming machine to accurately shape the profile required by the customer. Can be set to run in batches of multiple sizes.

Steel slitting line

Welded tube mill line high frequency

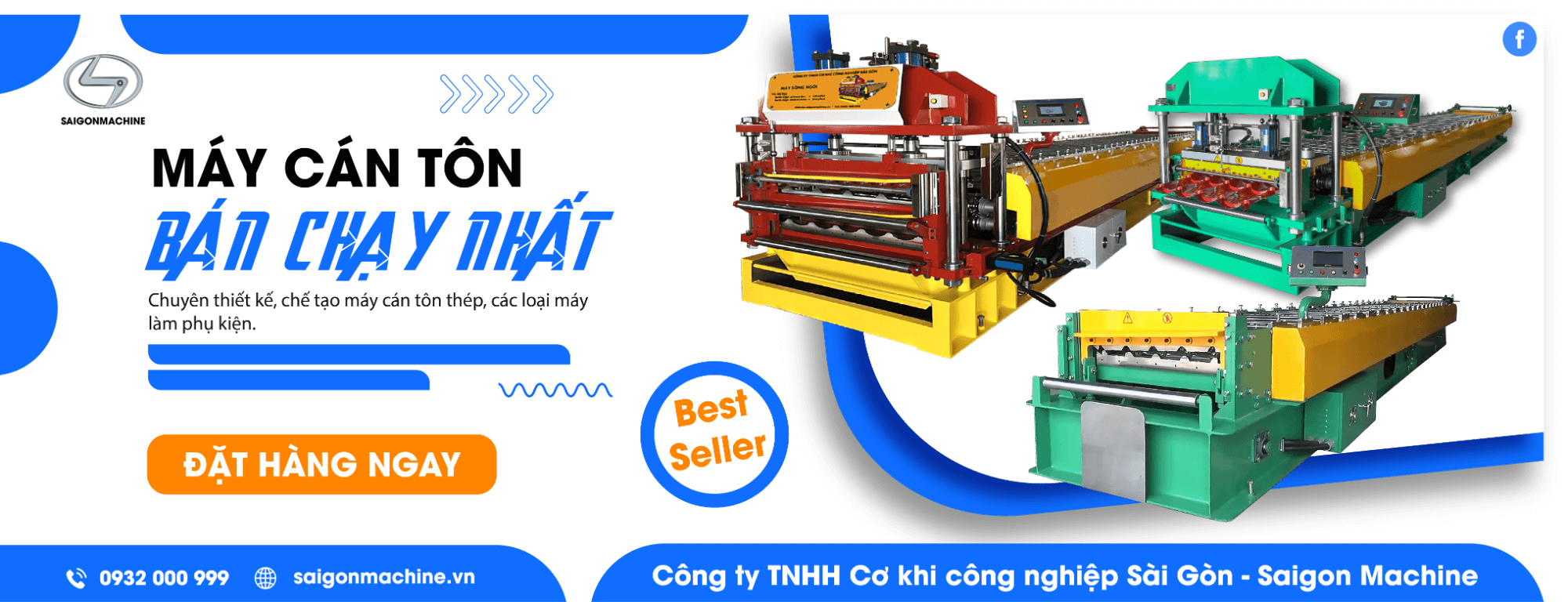

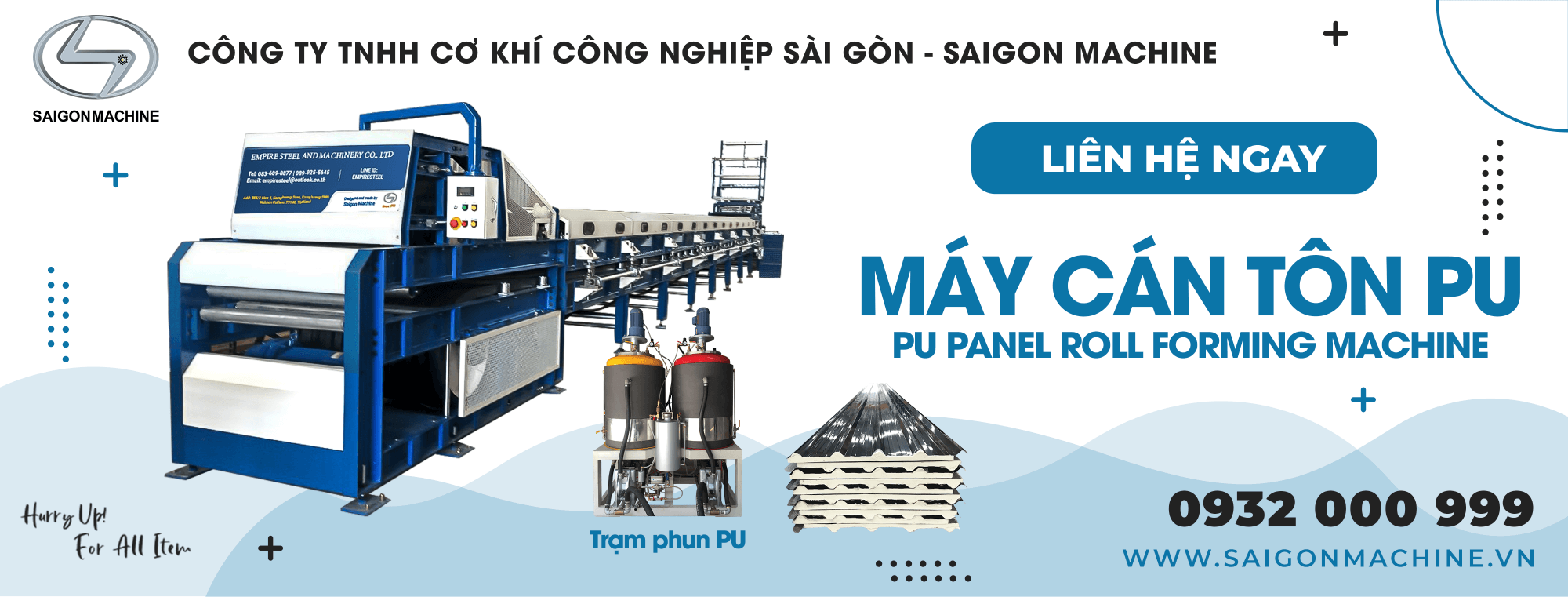

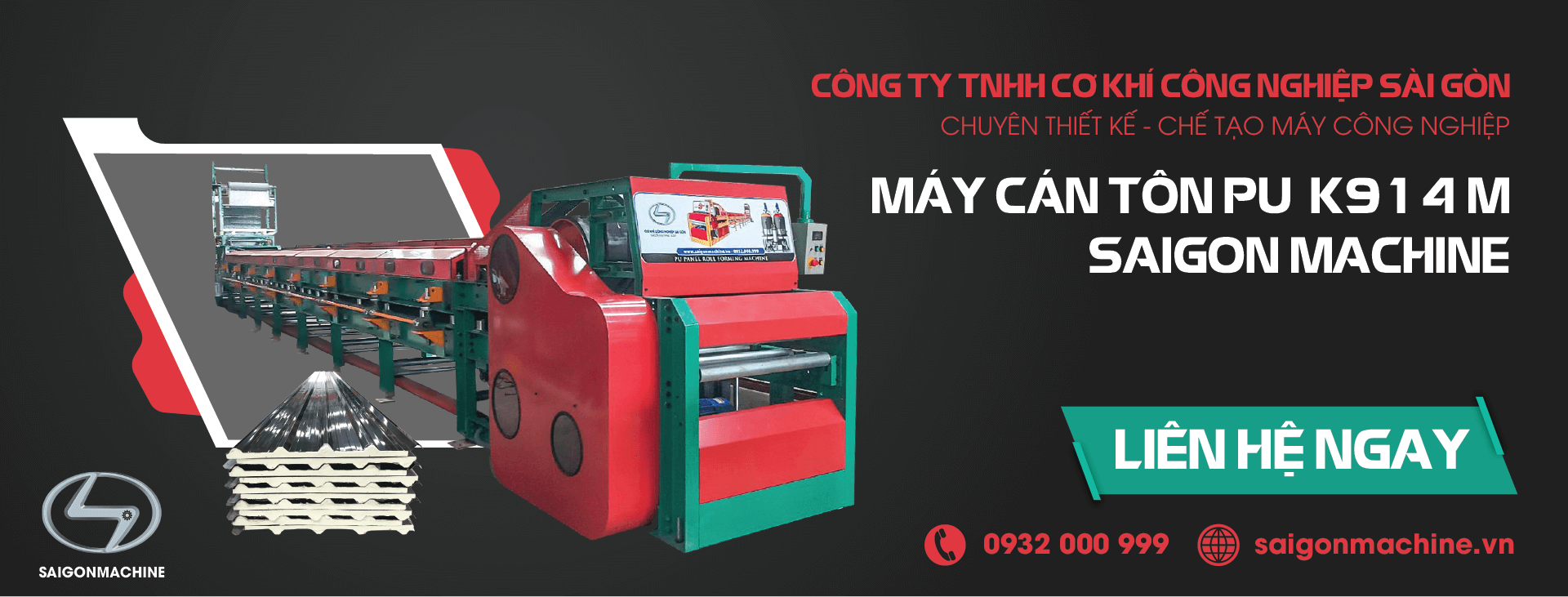

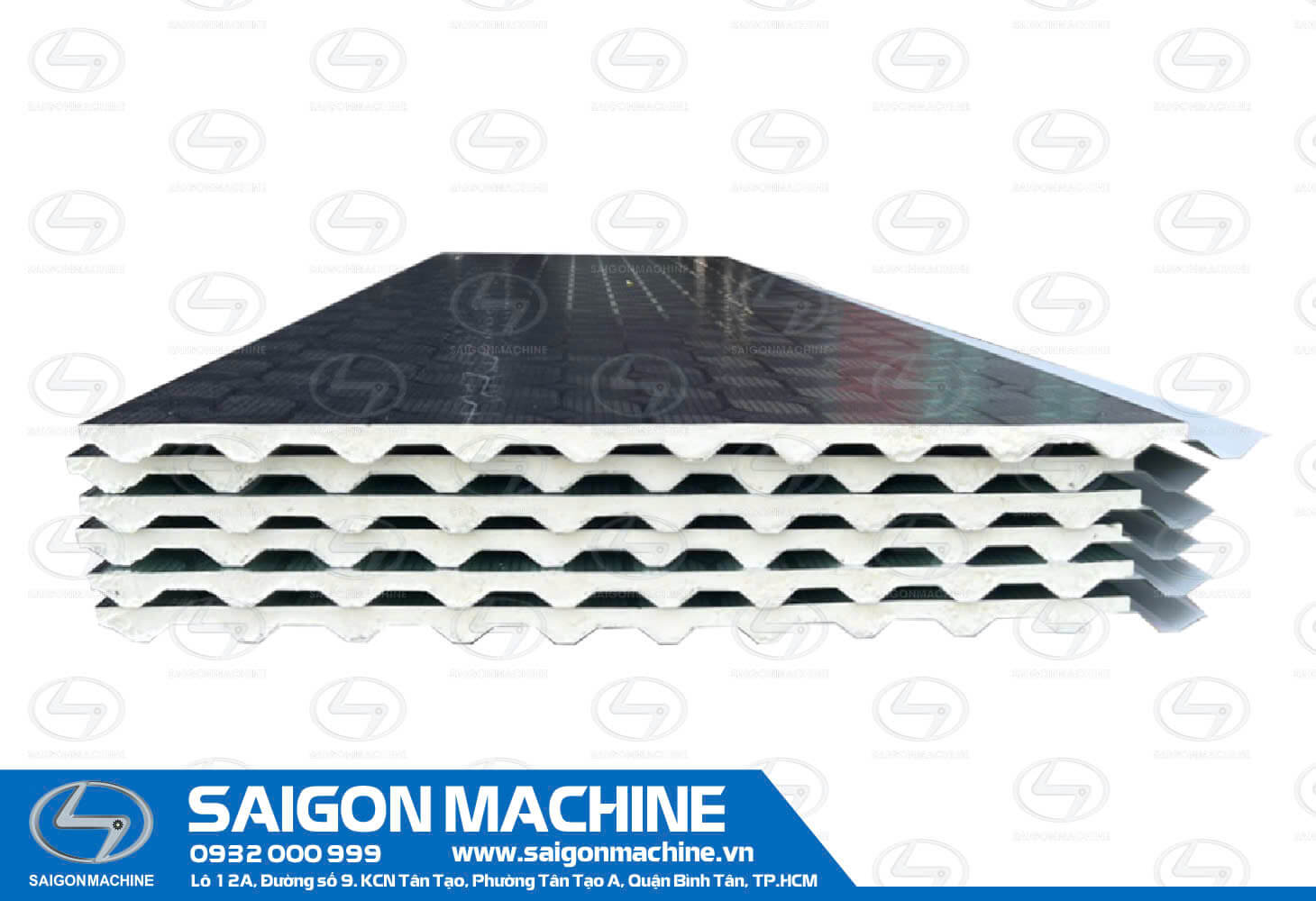

PU Assambly Line - Auto | PU Panel Roll Forming Machine - Auto

Saigon Machine - SGM, a reputable unit, specializing in supplying PU Assambly Line - Auto | PU Panel Roll Forming Machine - Auto creates brands of 3-layer corrugated iron, heat-insulated corrugated iron, cool corrugated iron, PU corrugated iron,... Currently, Foam sheet | PU corrugated iron is a product with high applications in life and is being supported by many people. With the advantages of easy construction and reasonable price, it is the first choice of many units. It can be said that Styrofoam | PU corrugated iron promises to be a product that completely replaces other roofing sheets in the future.

PU Assambly Line - Forming | PU Panel Roll Forming Machine - Forming

Saigon Machine - SGM, a reputable unit, specializing in supplying PU Assambly Line - Forming | PU Panel Roll Forming Machine - Forming creates brands of 3-layer corrugated iron, heat-insulated corrugated iron, cool corrugated iron, PU corrugated iron,... Currently, Foam sheet | PU corrugated iron is a product with high applications in life and is being supported by many people. With the advantages of easy construction and reasonable price, it is the first choice of many units. It can be said that Styrofoam | PU corrugated iron promises to be a product that completely replaces other roofing sheets in the future.

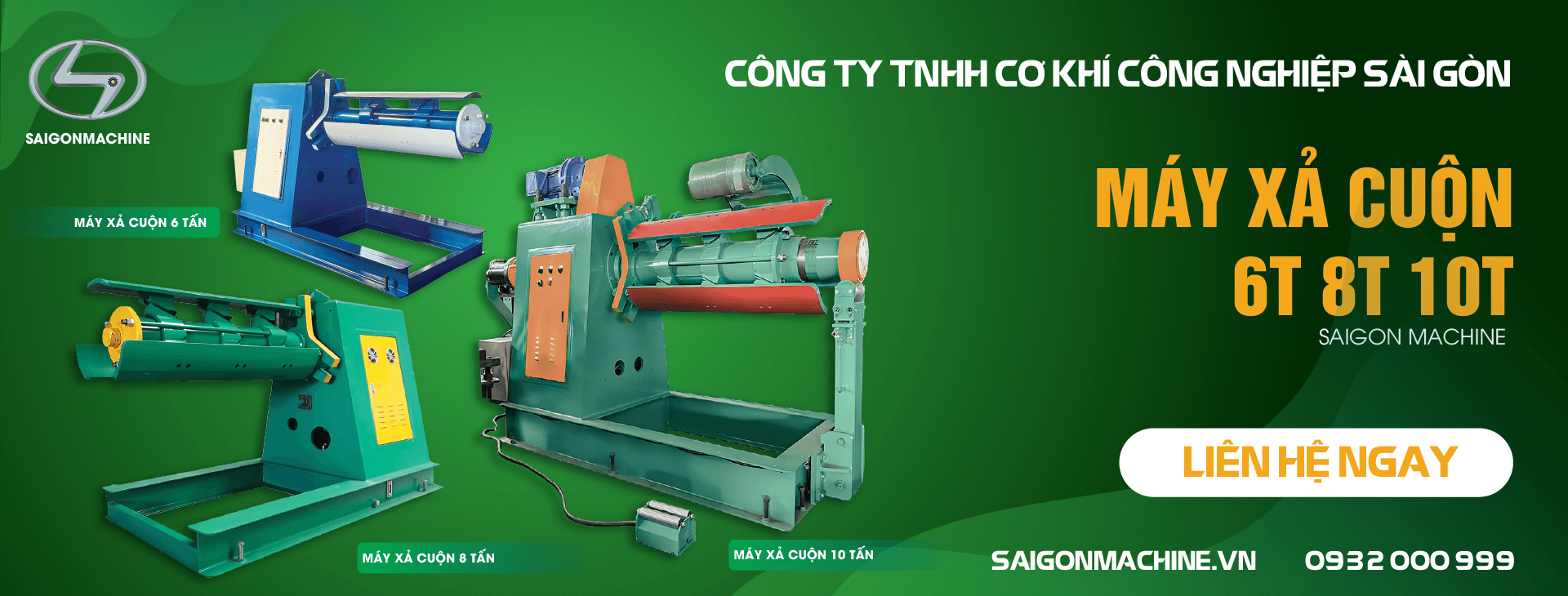

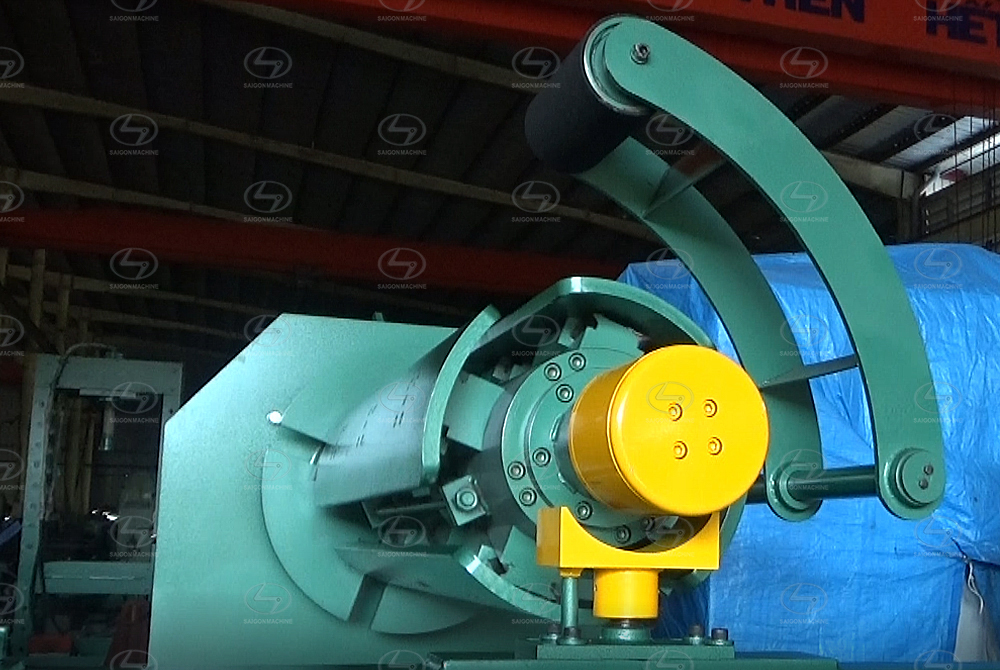

Auto - Uncoiler - Decoiler Machine - 10 Tons - Width 1300 mm

Auto - Uncoiler - Decoiler Machine - 10 Tons - Width 1300 mm, used to discharge steel coils, corrugated into steel sheets according to pre-specified sizes. The automatic winding machine system of Saigon Machine - SGM is manufactured at the factory by engineers from the factory directly installed at the customer's place.

Máy xả cuộn tự động - 08 tấn - Rãnh trượt - Van tỷ lệ

Máy xả cuộn tự động - 08 tấn - Rãnh trượt - Van tỷ lệ dùng để xả những cuộn thép, tôn ra thành tấm thép theo kích thước được qui định sẵn. Hệ thống máy xả cuộn tự động của Saigon Machine - SGM được sản xuất tại xưởng do các kĩ sư từ nhà máy trực tiếp lắp đặt tận nơi cho khách hàng.

Chúng tôi còn không ngừng cải tiến và phát triển sản phẩm nhầm đáp ứng mức độ phù hợp trong từng thời điểm của thị trường, có thể kể đến các dòng sản phẩm tương đồng như:

- Máy xả cuộn tự động - 06 tấn | Rãnh trượt | Van tỷ lệ

- Máy xả cuộn tự động - 06 tấn | Rãnh trượt | Van thường

- Máy xả cuộn tự động - 06 tấn | Ất quay | Van thường

Máy xả cuộn tự động - 06 tấn - Ất quay | Rãnh trượt

Máy xả cuộn tự động - 06 tấn - Ất quay | Rãnh trượt dùng để xả những cuộn thép, tôn ra thành tấm thép theo kích thước được qui định sẵn. Hệ thống máy xả cuộn tự động của Saigon Machine - SGM được sản xuất tại xưởng do các kĩ sư từ nhà máy trực tiếp lắp đặt tận nơi cho khách hàng.

Chúng tôi còn không ngừng cải tiến và phát triển sản phẩm nhầm đáp ứng mức độ phù hợp trong từng thời điểm của thị trường, có thể kể đến các dòng sản phẩm tương đồng như:

- Máy xả cuộn tự động - 06 tấn | Ất quay | Van thường

- Máy xả cuộn tự động - 06 tấn | Rãnh trượt | Van thường

- Máy xả cuộn tự động - 06 tấn | Rãnh trượt | Van tỷ lệ

- Máy xả cuộn tự động - 08 tấn | Rãnh trượt | Van tỷ lệ

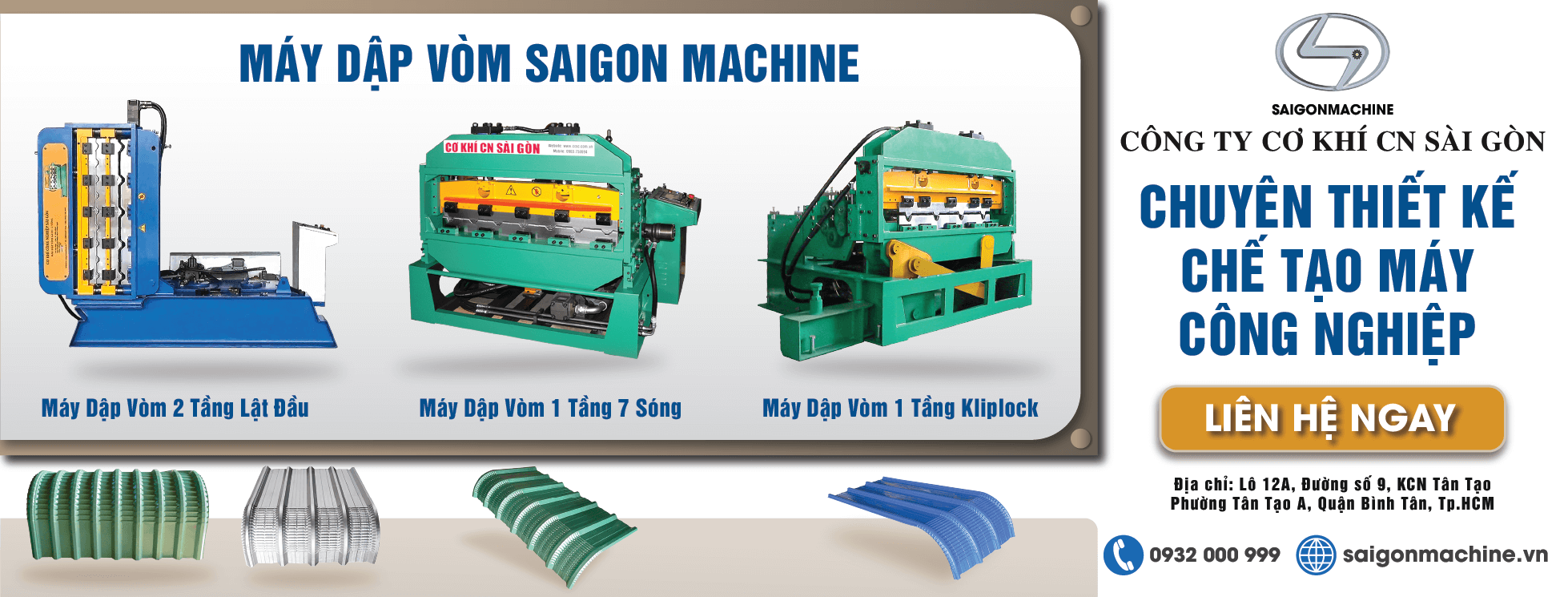

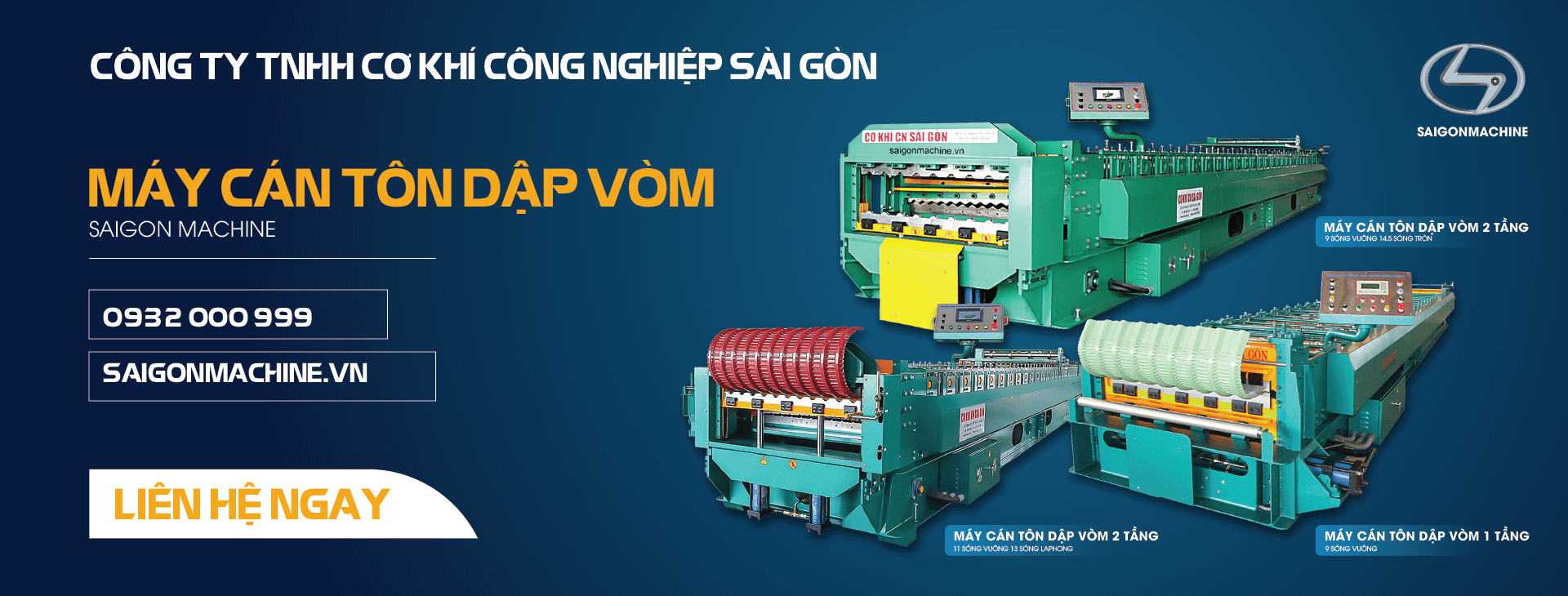

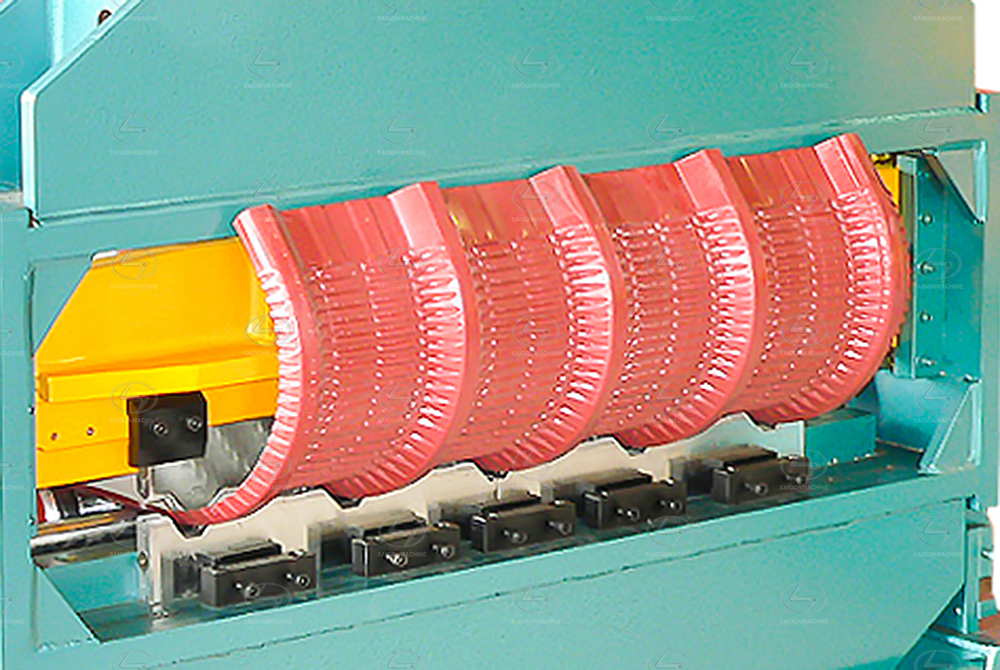

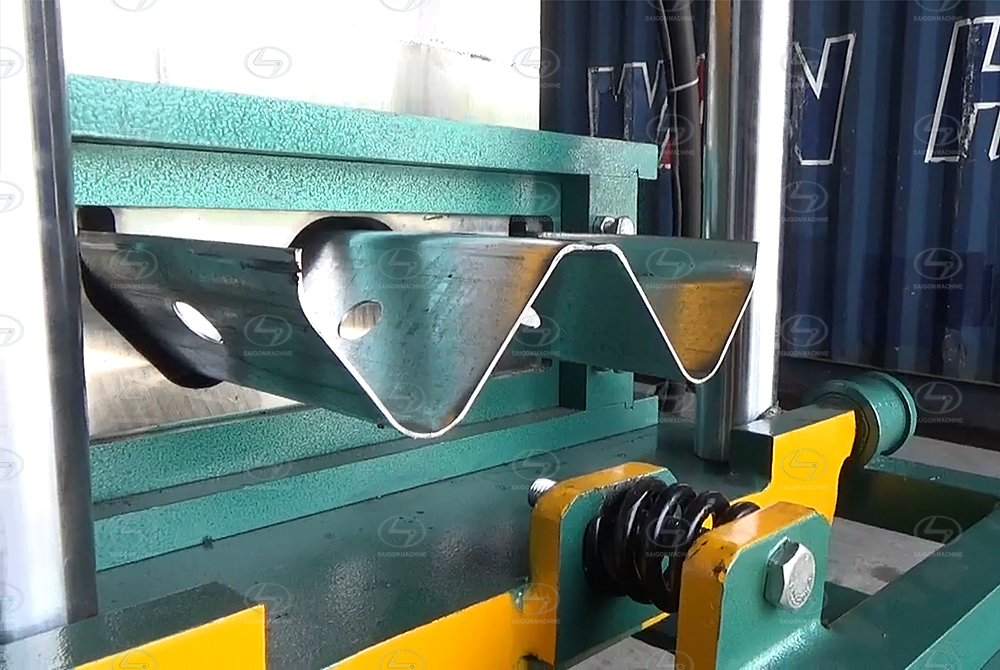

Single layer - Crimp curving machine - Vertical & Horizontal

Single layer - Crimp curving machine - Vertical & Horizontal, has a very complex structure so that it can create many products with many different applications.

The first thing to mention is the application of creating different types of arches with different curved shapes and designs. With the creation of curved roof arches have been used in many of the eaves to cover the sun and rain. At the same time, those domes are created with many different designs, so they can be used in many different awning spaces. In addition, the machine also creates mechanical products to assemble into spaces that need to use the curvature of products such as car rims, machine rims, equipment in life that need to be bent...

With the above application, it shows that the stamping machine is a very useful and necessary machine in today's life. Therefore, it is widely used by many mechanical manufacturing facilities.

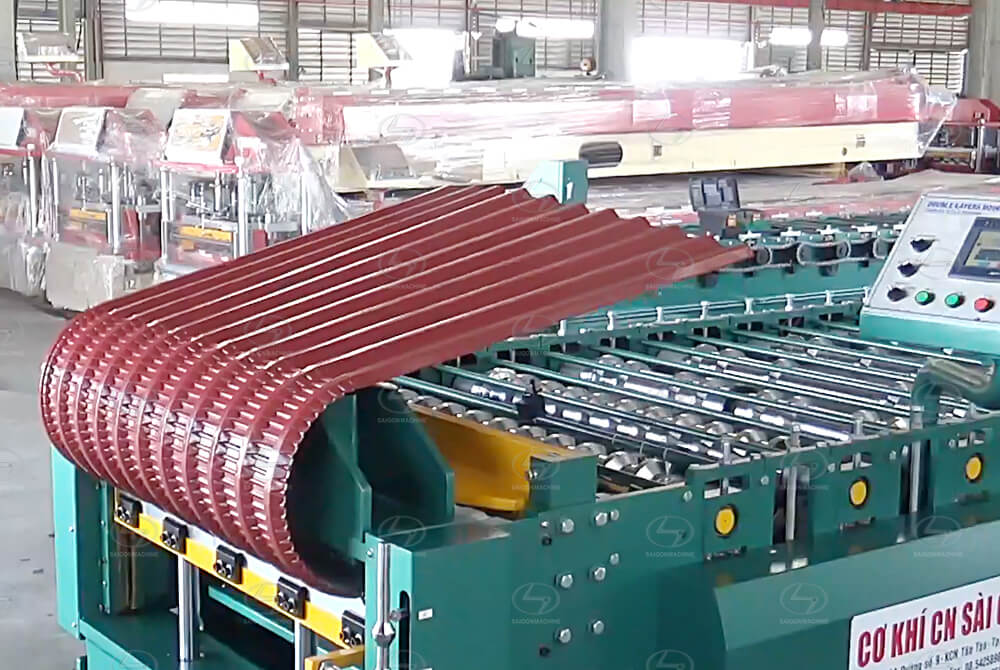

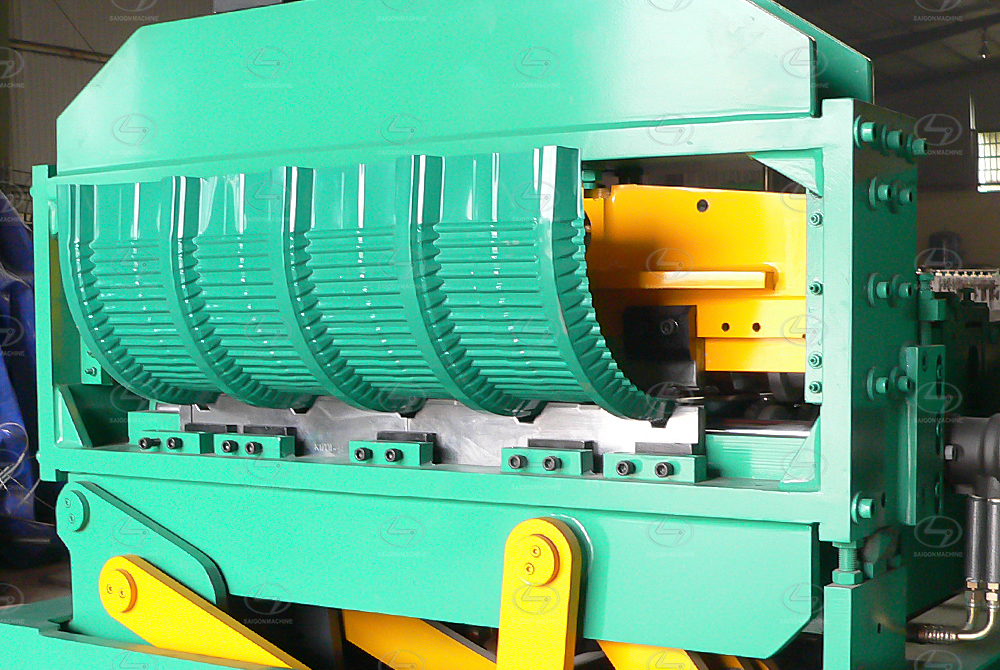

Double layer - Crimp curving machine - Vertical & Horizontal

Double layer - Crimp curving machine - Vertical & Horizontal, has a very complex structure so that it can create many products with many different applications.

The first thing to mention is the application of creating different types of arches with different curved shapes and designs. With the creation of curved roof arches have been used in many of the eaves to cover the sun and rain. At the same time, those domes are created with many different designs, so they can be used in many different awning spaces. In addition, the machine also creates mechanical products to assemble into spaces that need to use the curvature of products such as car rims, machine rims, equipment in life that need to be bent...

With the above application, it shows that the stamping machine is a very useful and necessary machine in today's life. Therefore, it is widely used by many mechanical manufacturing facilities.

Single layer - Crimp curving machine - Vertical

Single layer - Crimp curving machine - Vertical, has a very complex structure so that it can create many products with many different applications.

The first thing to mention is the application of creating different types of arches with different curved shapes and designs. With the creation of curved roof arches have been used in many of the eaves to cover the sun and rain. At the same time, those domes are created with many different designs, so they can be used in many different awning spaces. In addition, the machine also creates mechanical products to assemble into spaces that need to use the curvature of products such as car rims, machine rims, equipment in life that need to be bent...

With the above application, it shows that the stamping machine is a very useful and necessary machine in today's life. Therefore, it is widely used by many mechanical manufacturing facilities.

Single layer - Roll forming machine - Roof tile | Glazed tile

Products Roof tile | Glazed tile, usually used for roofs with multi-roof architecture in the style of villas or roofs with steep slopes. Using Roof tile | Glazed tile, roofing will reduce a lot of load on the roof frame, columns and foundation compared to conventional tile roofing.

The waveform is designed in the style of ROOF TILE STYLE BAMBOO | ROOF TILE STYLE WEST | ROOF TILE STYLE LEAN | ROOF TILE STYLE CPAC | ROOF TILE STYLE SAKURA | ROOF TILE STYLE RUBY | ROOF TILE STYLE BLUESCOPE | ROOF TILE STYLE VENIS | ROOF TILE STYLE INDONESIA with many different colors and thicknesses for customers to choose from. Users also save a lot of other costs for the roof compared to roofing with conventional brick tiles while ensuring safety and saving costs for users.

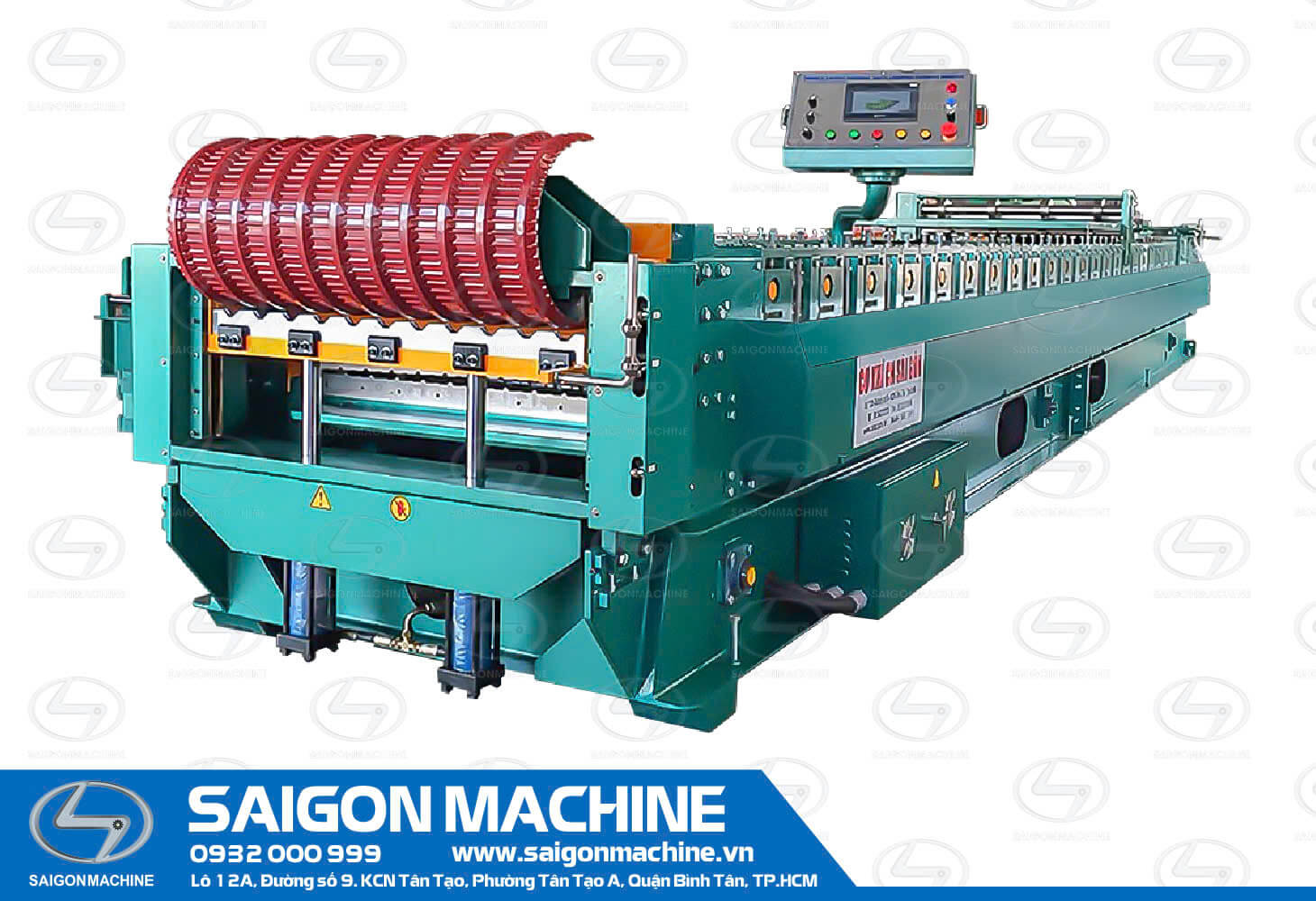

Double layer - Roll forming machine - Roof tile | Glazed tile - Ribs roof trapezoidal | Circulars corrugated | Ribs roof plafonds

Products Roof tile | Glazed tile, usually used for roofs with multi-roof architecture in the style of villas or roofs with steep slopes. Using Roof tile | Glazed tile, roofing will reduce a lot of load on the roof frame, columns and foundation compared to conventional tile roofing.

The waveform is designed in the style of ROOF TILE STYLE BAMBOO | ROOF TILE STYLE WEST | ROOF TILE STYLE LEAN | ROOF TILE STYLE CPAC | ROOF TILE STYLE SAKURA | ROOF TILE STYLE RUBY | ROOF TILE STYLE BLUESCOPE | ROOF TILE STYLE VENIS | ROOF TILE STYLE INDONESIA with many different colors and thicknesses for customers to choose from. Users also save a lot of other costs for the roof compared to roofing with conventional brick tiles while ensuring safety and saving costs for users.

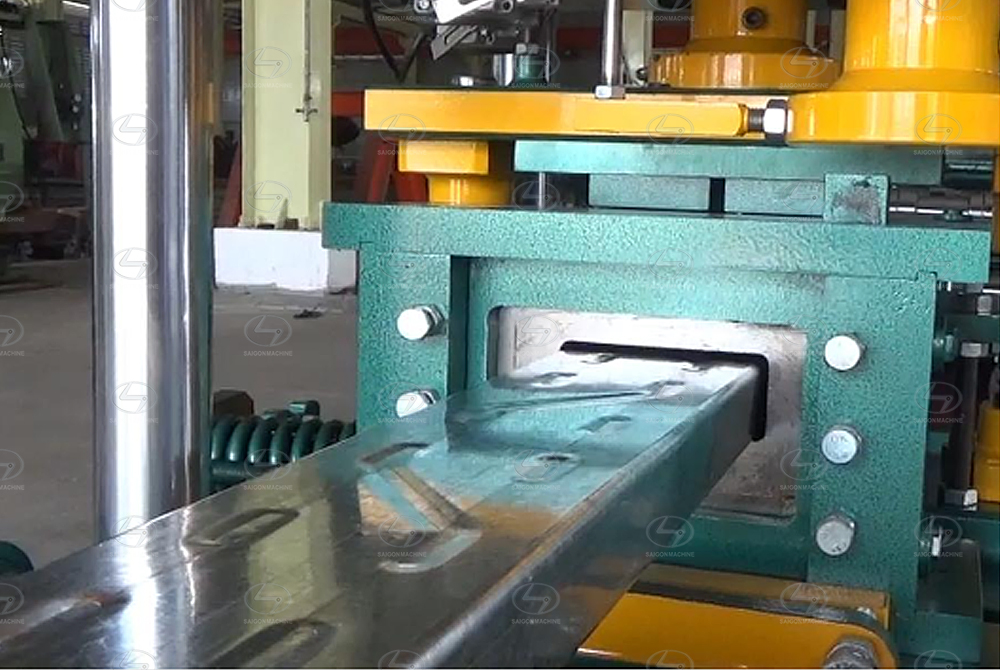

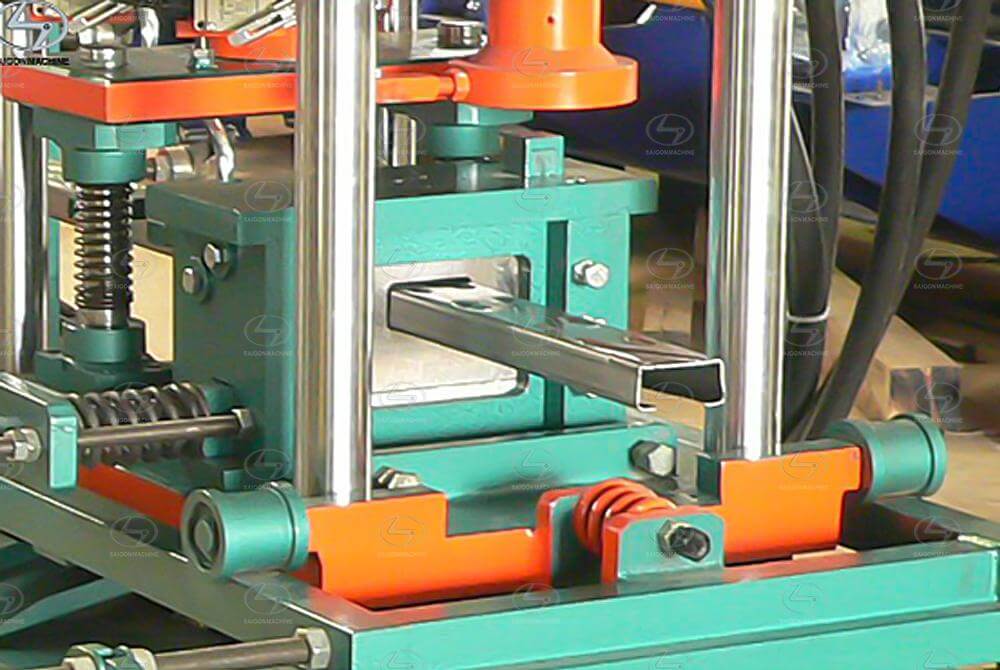

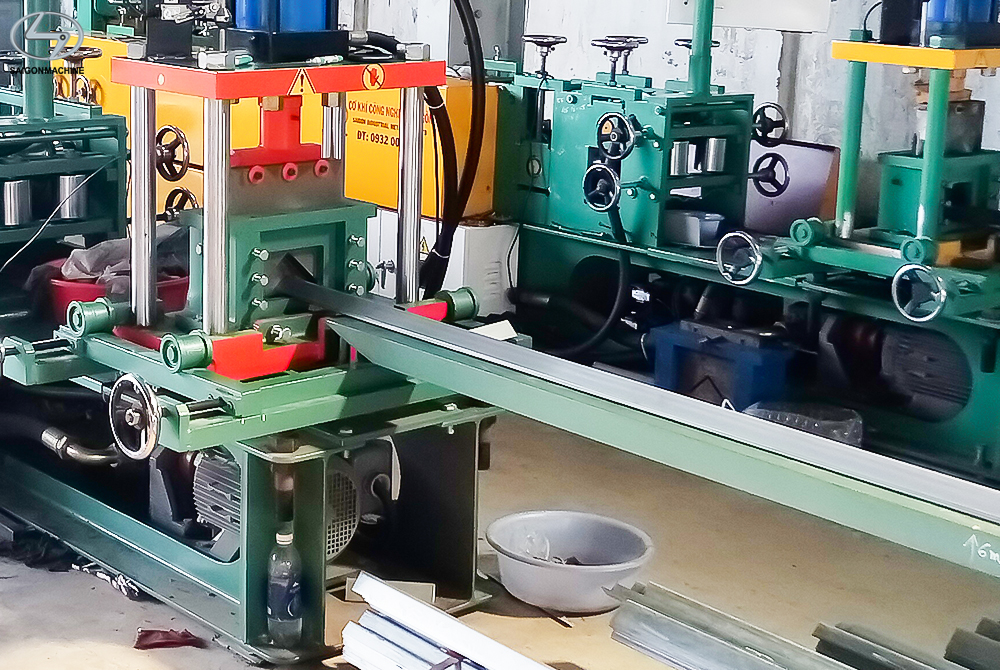

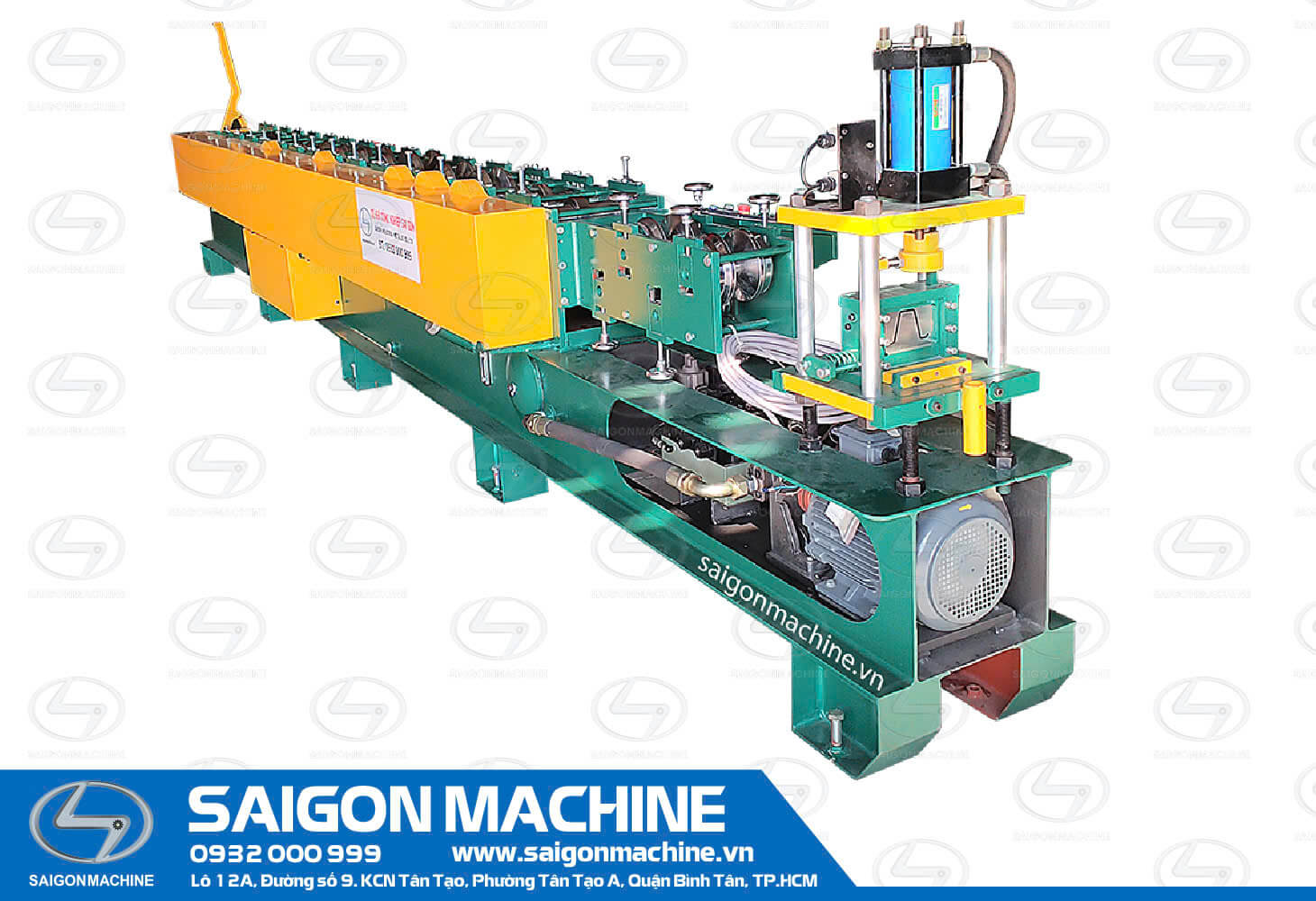

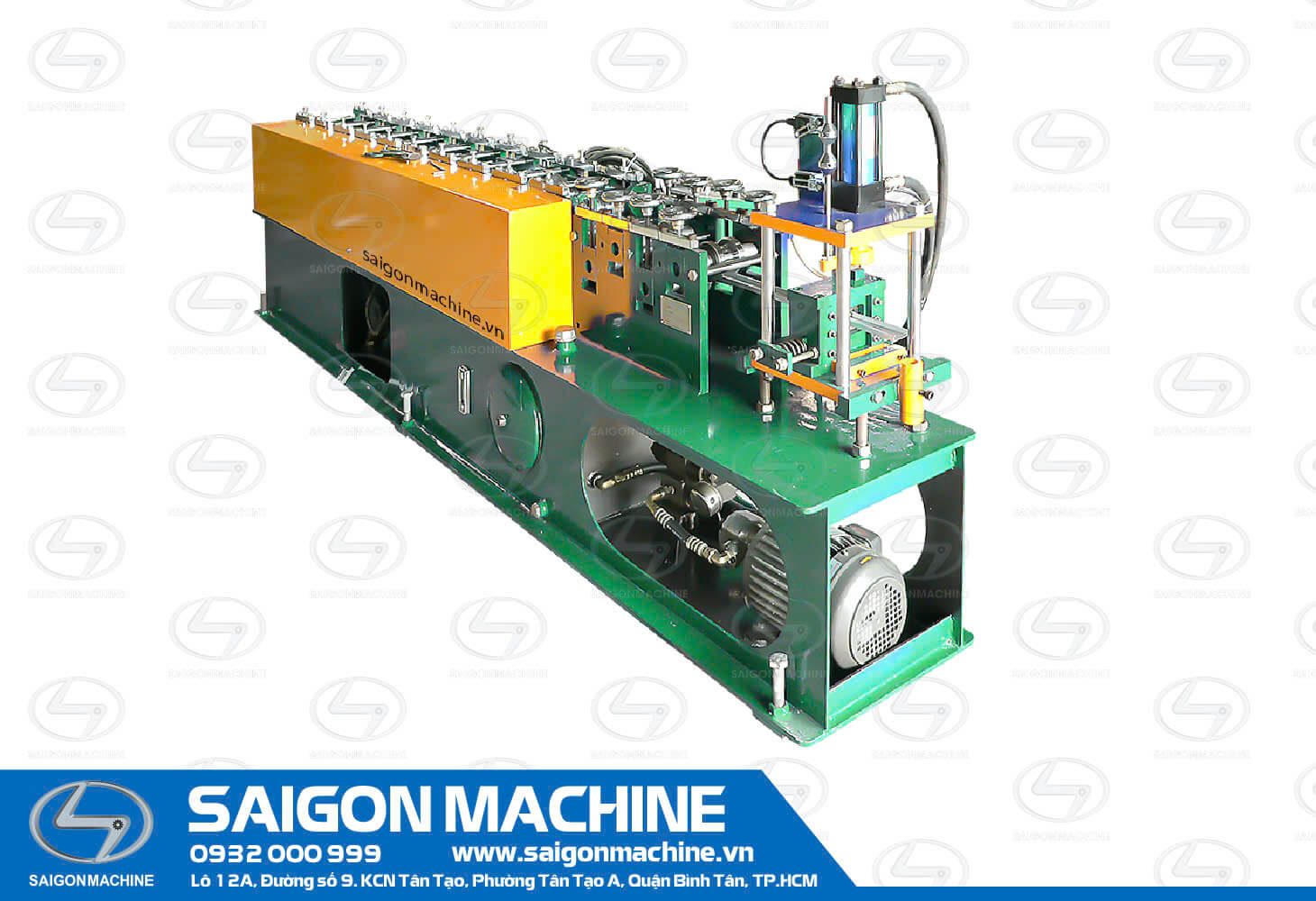

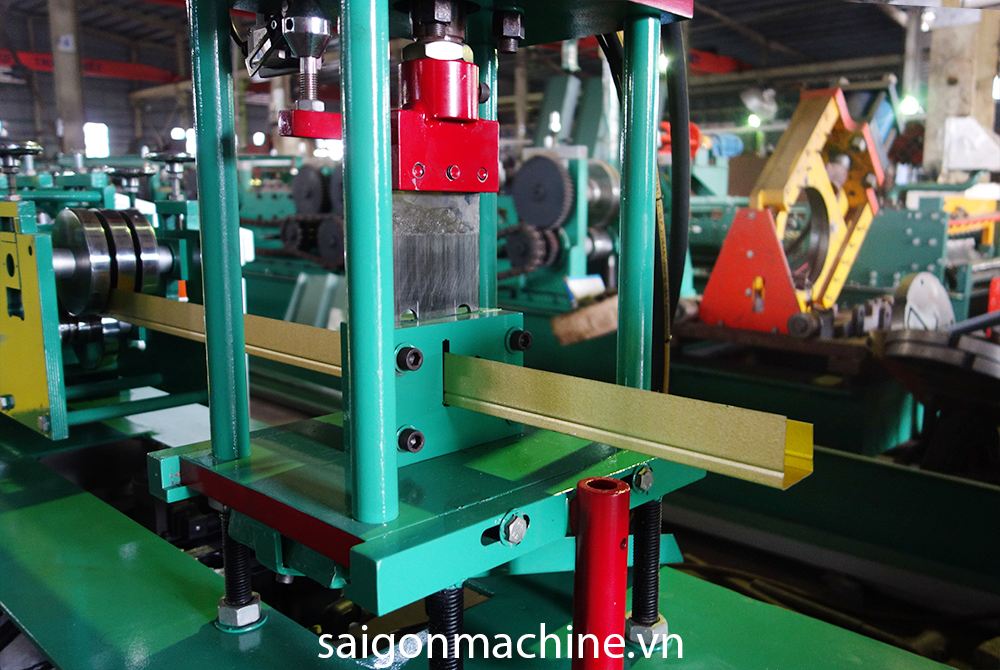

C200 - Purlin roll forming machine - 1 Punching station | 2 Punching stations | 3 Punching stations

Saigon Industrial Mechanical Co., Ltd | Saigon Machine - SGM manufactures and supplies C200 - Purlin roll forming machine - 1 Punching station | 2 Punching stations | 3 Punching stations, installed in Vietnam with components imported from abroad such as Korea, Japan, Taiwan… Product C200 - Purlin roll forming machine - 1 Punching station | 2 Punching stations | 3 Punching stations, widely applied in civil and industrial constructions.

Auto - C200 | U200 - Purlin roll forming machine - 1 Punching station

C300 - Purlin roll forming machine - 1 Punching station | 2 Punching stations | 3 Punching stations

Z300 - Purlin roll forming machine - 1 Punching station | 2 Punching stations | 3 Punching stations

Saigon Industrial Mechanical Co., Ltd | Saigon Machine - SGM manufactures and supplies Z300 - Purlin roll forming machine - 1 Punching station | 2 Punching stations | 3 Punching stations, installed in Vietnam with components imported from abroad such as Korea, Japan, Taiwan… Product Z300 - Purlin roll forming machine - 1 Punching station | 2 Punching stations | 3 Punching stations make up widely applied in civil and industrial constructions.

Auto - C300 | Z300 - Purlin roll forming machine - 3 Punching stations

C75 | C80 - Batten roll forming machine - Indonesia

C75 | C100 - Batten roll forming machine

V32 | V42 | V61 - Batten roll forming machine

V25 - V75 - Batten roll forming machine - Speed 60m/min

V25 | V30 - Batten roll forming machine - Indonesia

U41 - Shaped steel bar roll forming machine

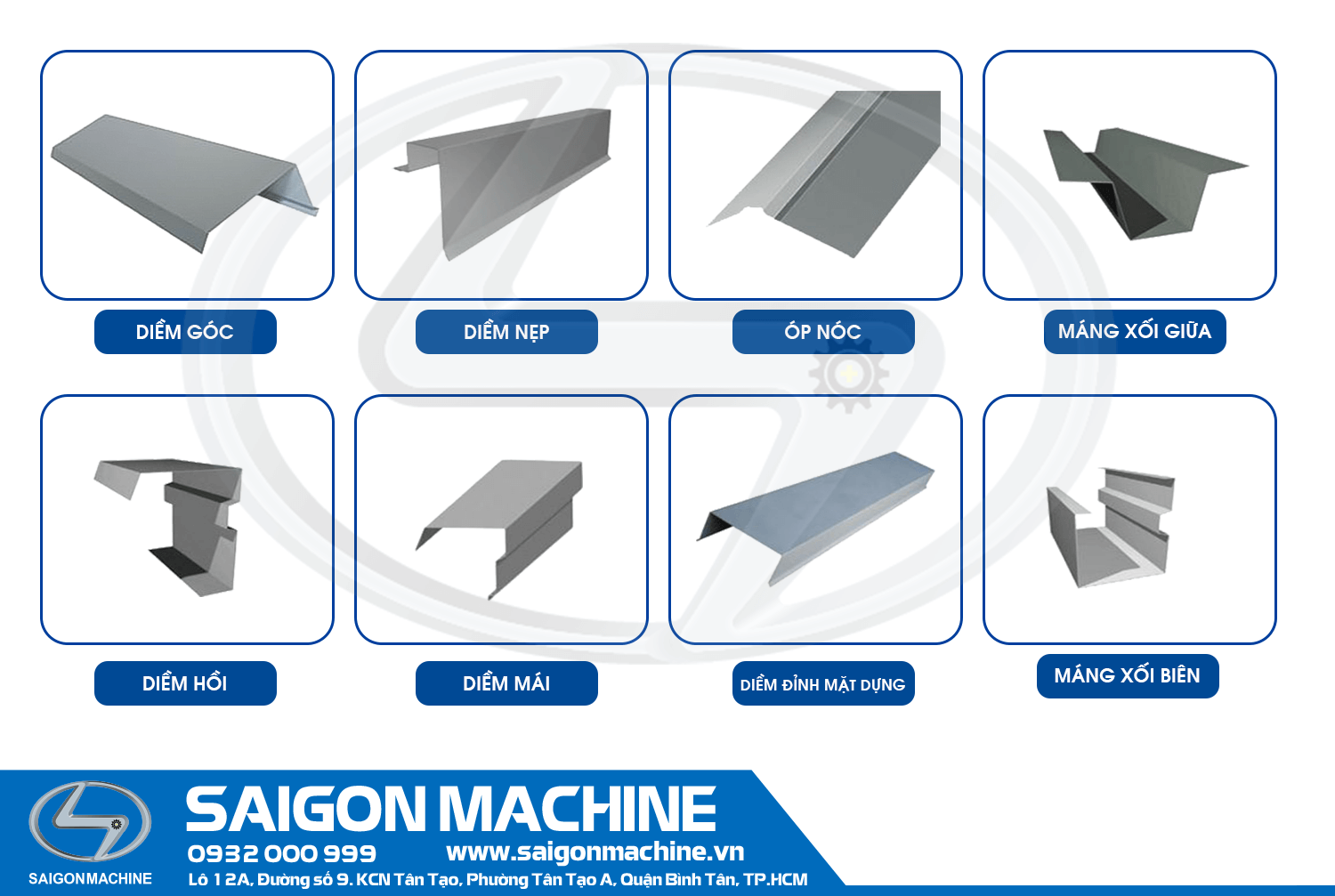

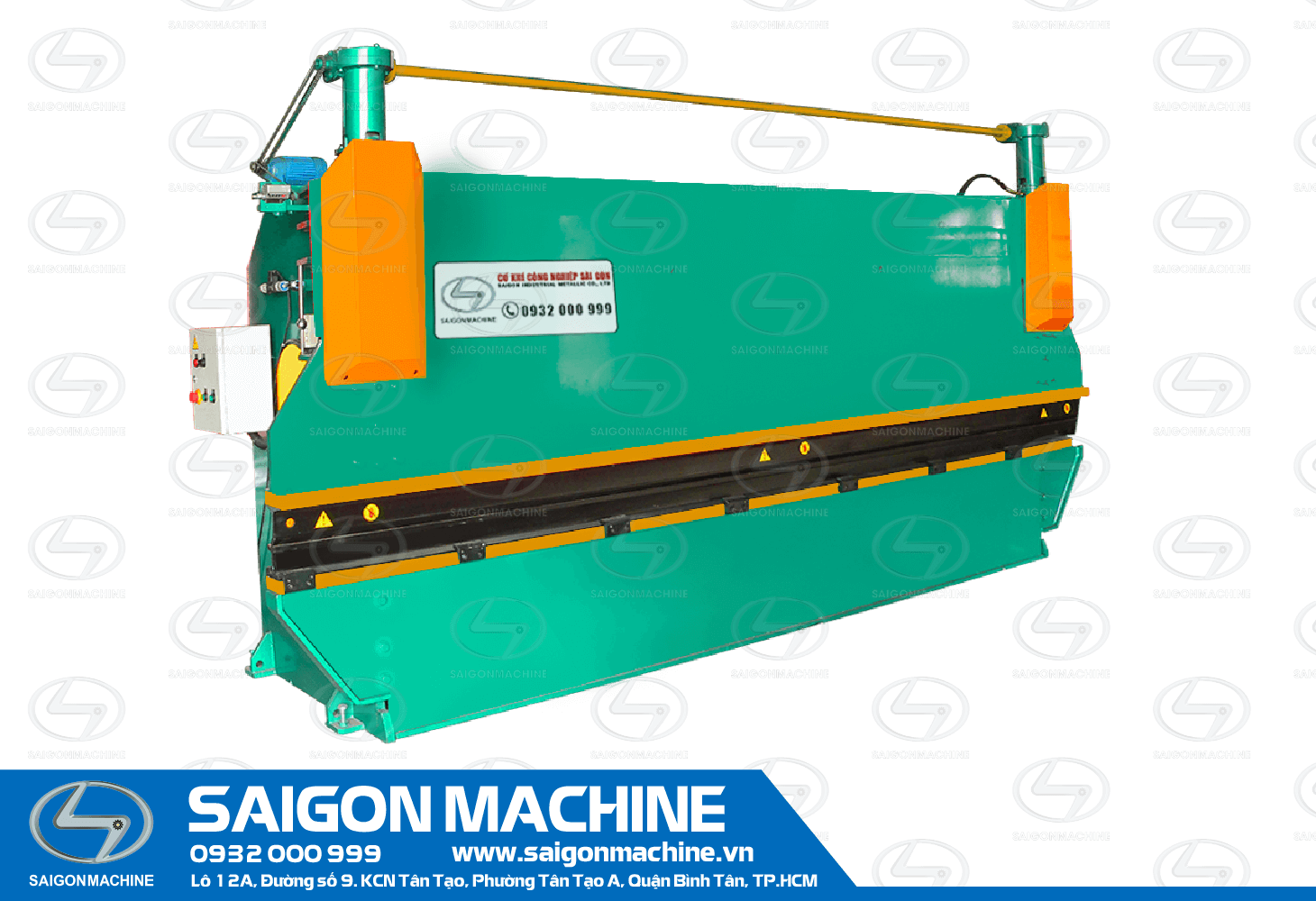

Press brake machine - Auto angle adjustable - 6.1M - H612

Press brake machine - Auto angle adjustable - 4.5M - H350

Press brake machine - Auto angle adjustable - 4.5M - H350 has a range of familiar applications that you can easily find anywhere you look. Typical applications can be mentioned as corrugated iron roofs, iron and steel parts of appliances, machinery and countless other applications. Press brake machine - Auto angle adjustable - 4.5M - H350 is "a real machine" with a sturdy, robust design that ensures efficient response to the needs of large factories.

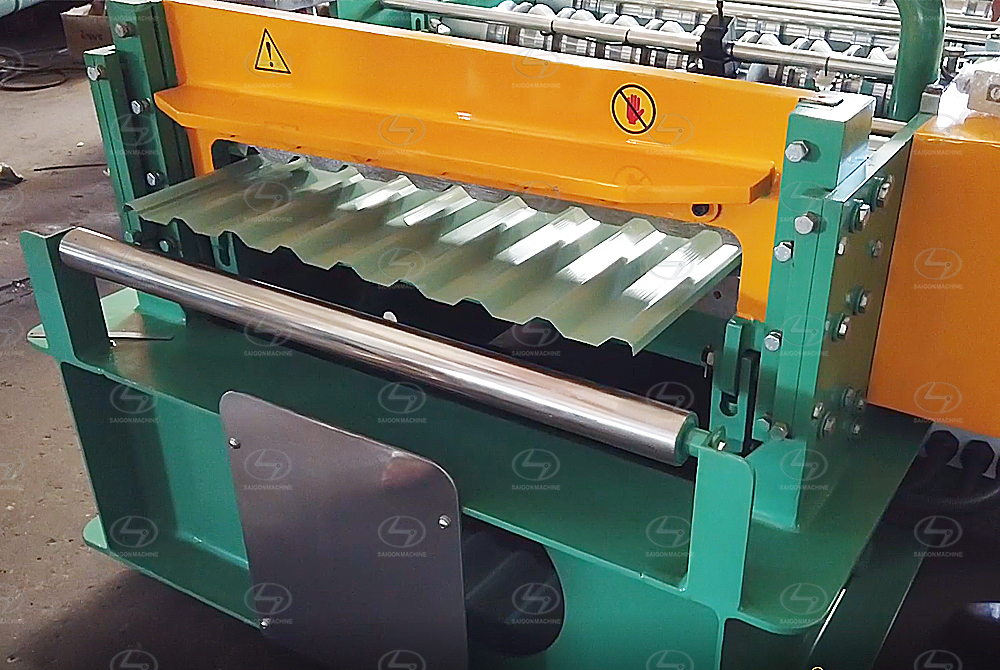

Corrugated iron folding machine | Corrugated iron breaking machine - 4.5M

With unique design of bending and toughening alloy rolling part, Corrugated iron folding machine | Corrugated iron breaking machine - 4.5M can save working space and ensure its service life. Besides, Corrugated iron folding machine | Corrugated iron breaking machine - 4.5M has combined several functions to maximize working efficiency, high durability, thus can guarantee the working accuracy. With reasonable size, convenience in moving and adapting to different working environments.

Press brake machine - Auto angle adjustable - 9M - H620

Press brake machine - Auto angle adjustable - 9M - H620 is optimally designed for stable, precise, user-friendly operation and high productivity. Stamping / Press is a flat steel plate deformation process, which is the processing process immediately after the cutting process. The work piece is placed directly on the bending die with a V-shaped mouth and can therefore be bent to the desired angle.