Double layer - Crimp curving machine - Vertical & Horizontal

Double layer - Crimp curving machine - Vertical & Horizontal, has a very complex structure so that it can create many products with many different applications.

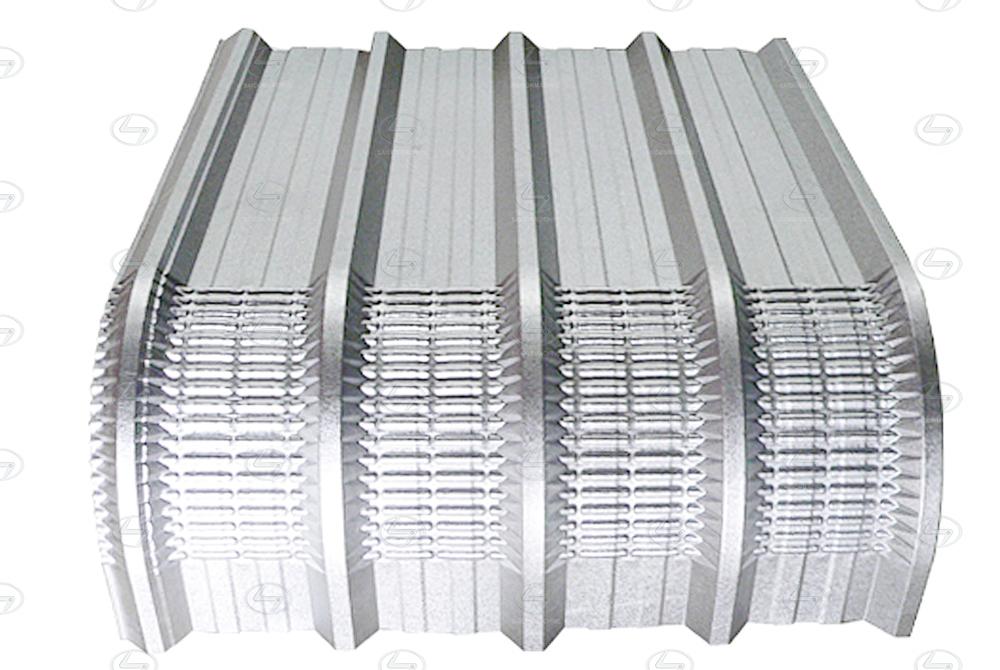

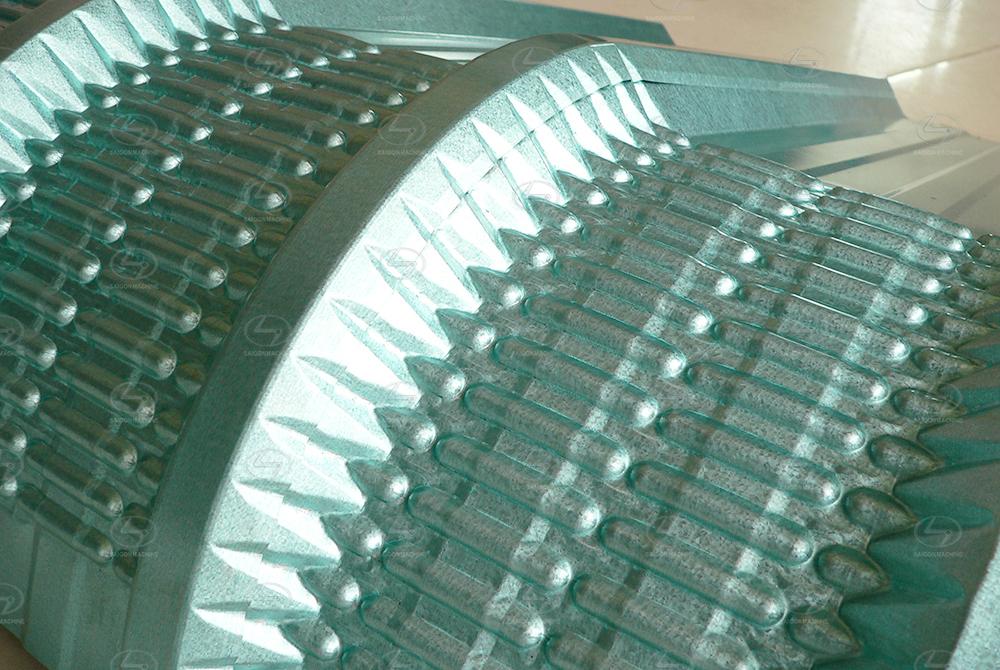

The first thing to mention is the application of creating different types of arches with different curved shapes and designs. With the creation of curved roof arches have been used in many of the eaves to cover the sun and rain. At the same time, those domes are created with many different designs, so they can be used in many different awning spaces. In addition, the machine also creates mechanical products to assemble into spaces that need to use the curvature of products such as car rims, machine rims, equipment in life that need to be bent...

With the above application, it shows that the stamping machine is a very useful and necessary machine in today's life. Therefore, it is widely used by many mechanical manufacturing facilities.

Projects

CÔNG TY TNHH TM - DV SẮT THÉP THÁI DƯƠNG (CỦ CHI)-

HỘ KINH DOANH PHẠM HỒNG THÁI - VĨNH LONG

CÔNG TY TNHH TÔN THÉP ANH KHANG - VŨNG TÀU

CÔNG TY TNHH SX TM SÁU BÌNH MINH

CÔNG TY TRÁCH NHIỆM HỮU HẠN SONG HỶ

CÔNG TY TNHH MTV HOÀNG PHÁT - ÚT

Description

-

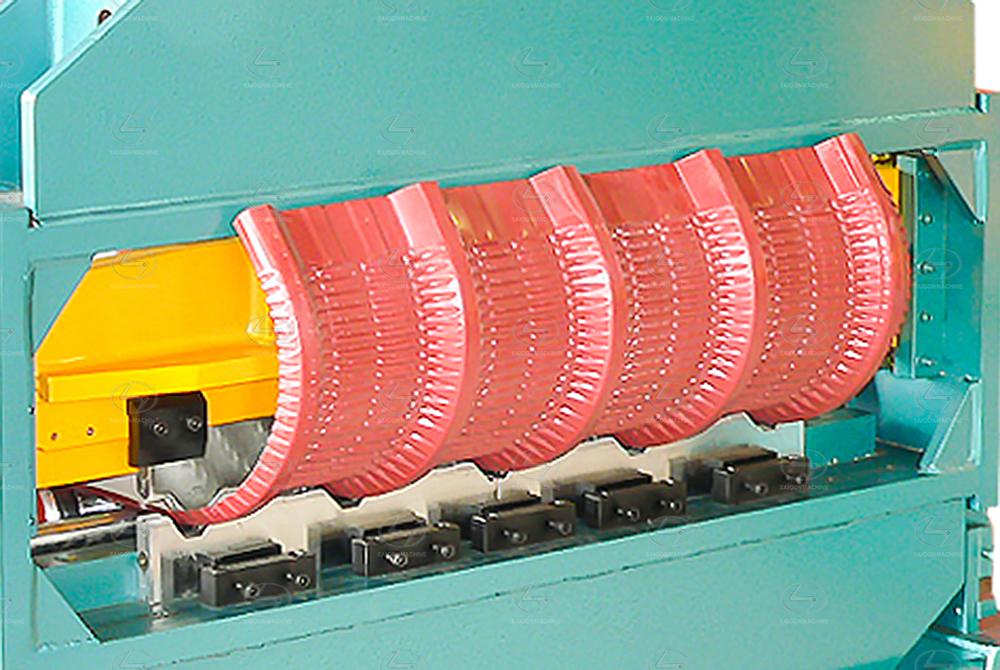

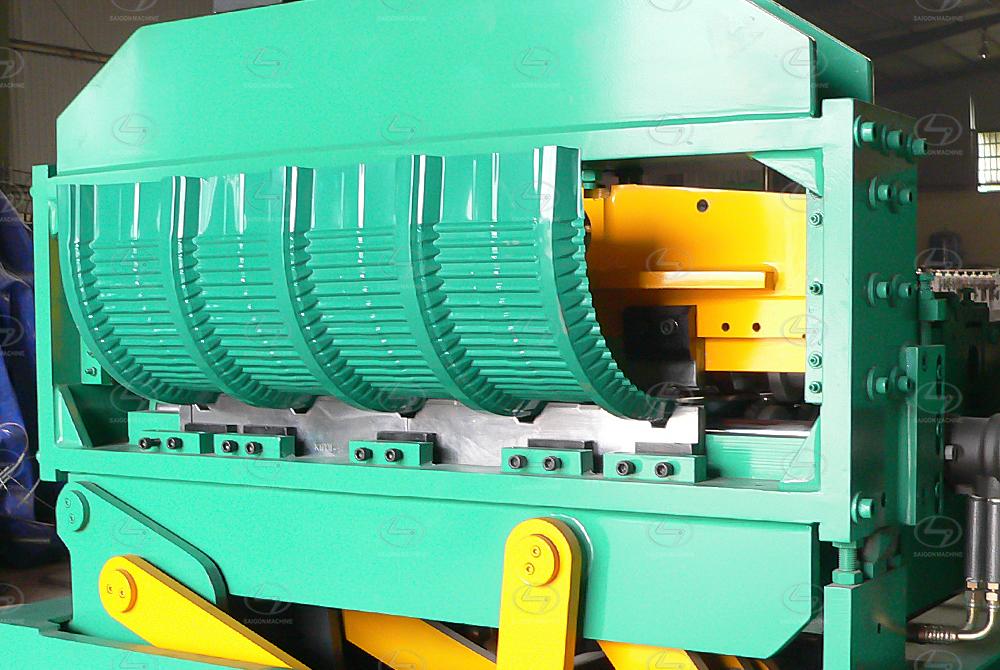

The basic structure of Double layer - Crimp curving machine - Vertical & Horizontal

1. Double layer - Crimp curving machine - Vertical & Horizontal, currently has many types on the market, it has different sizes, however, their sizes are mostly large with a weight of tons, so owning an arch press is often are factories, production workshops, mechanical manufacturing…

2. Regarding the external structure of the machine, you can see that it has a body structure to contain the motor, the engine inside. Along with that is a thick machine wall that is used to create curved domes, a thick base to help the arch stamping machine stand. The outer surface of the machine is mostly rolled and plated with Chrome.

3. The internal structure of the machine includes 1 set of 5.5kw motor and pump, 1 pressure switch, 1 stamping ball, 1 set of stamping dies, 4 arch stamping shafts and 3 corrugated iron guide shafts and a control cabinet, 1 motor hydraulic.

4. Using the high-speed counter 2000 Pulses / Rev. 7 times more accurate than the 360 Pulse/Round type.

5. The stamping buttons when roofing fit snugly from the beginning to the end.

6. The machine works continuously, programmed by smart software, resets itself without a switch when changing from one plate to another.

=> With the above structure shows, a stamping machine is very complicated with many parts inside. However, on the outside, the structure is very simple.

-

Some advantages of Double layer - Crimp curving machine - Vertical & Horizontal, that we can mention are as follows:

1. The machine has a large stamping speed and high production efficiency, so users can save more time and still get the desired results.

2. The machine delivers high productivity, more products in less time.

3. Saving the labor of workers: To make a arched arch requires a lot of stages and meticulousness. Therefore, if it depends only on human power, the productivity will be very low. While using the machine, it only takes 1-2 people to operate the machine, but the product quality is still guaranteed.

4. Bring the lowest cost and price: This is because you don't have to pay to hire too many workers, time and productivity are always guaranteed...

Video Product

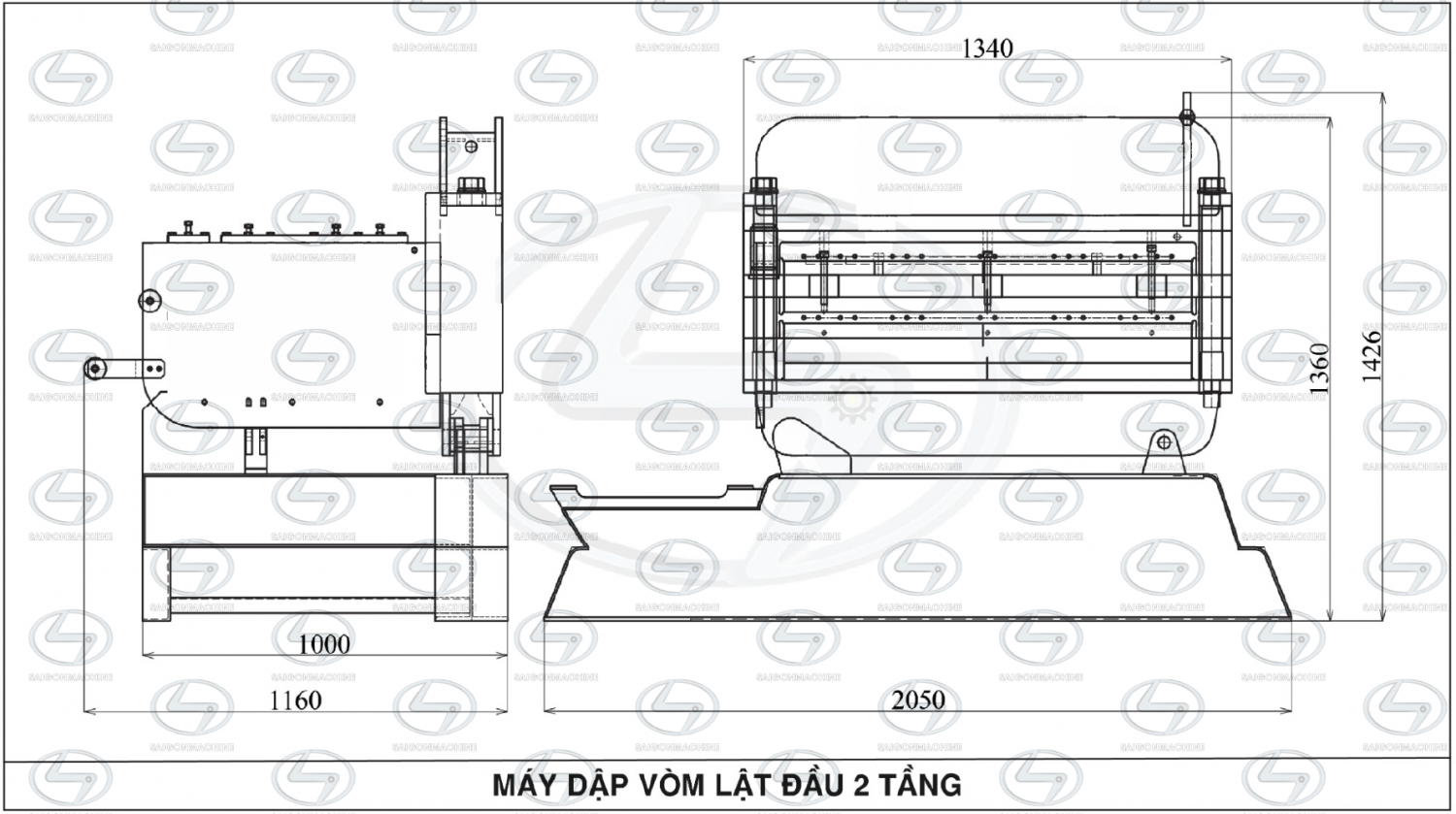

Layout Machine

SPECIFICATIONS

Thông số máy

-

Kích thước (D x R x C)2300 mm x 1200 mm x 1400 mm

-

Trọng lượng (Kg)1960 Kg

-

Năng suất / tốc độ (Tấm/h)80 Tấm/h ÷ 90 Tấm/h

(Theo tiêu chuẩn: Dập vòm cong đạt 90° với tôn dài 1m và dập 16 => 18 nút dập / Tấm) -

Cặp trục kéo chính2 cặp dẫn hướng

-

Trục dẫn hướng phụ1 cặp

-

Đường kính trục cán (mm)Ø57 mm

-

Công suất điện (KW / HP)3.7 KW / 5 HP

Thông số nguyên liệu

-

Chiều rộng khổ tôn (mm)1000 mm (Max)

-

Độ dày (mm)0.25 mm ÷ 0.5 mm

-

Độ cứngG300 - G550

Thủy lực

-

Motor điệnHitachi

-

Đầu bơm (Cm³/v)23 Cm³/v

-

VanVan điện tử 03

-

Giải nhiệt (Quạt)Không

-

Ống dầuYokohama / Dynesflex

-

Motor truyền động (cc/v)MS - 400 cc/v + Xích tải kép

-

Đồng hồ áp (Kg/cm²)250 Kg/cm² (Nhật Bản)

-

Dầu thủy lực R32 (Nhập khẩu)150L

Tủ điện điều khiển

-

CB nguồnFuji - Mitsu - Nhật Bản

-

Rơlay chống quá tải bảo vệ động cơCó

-

Bo nguồnOmron 24VDC

-

Bộ điều khiển công nghiệp (PLC)Siemens - Đức

-

Màn hìnhWeintek - Đài Loan

-

Rơlay đóng ngắt van thủy lựcTiếp điểm đóng ngắt siêu bền chịu tải 10A - Idec - Izumi - Nhật Bản

-

Bo tỷ lệ điều khiển tốc độCó

-

Tủ điều khiểnTủ đứng

-

Bộ đếm chiều dàiOmron / Autonics (2000 Xung / Vòng) - Bộ đếm xung tốc độ cao đảm bảo máy chạy nhanh nhưng không sai số bước dập

-

Dây điệnViệt Nam

Bộ phận dập - cắt và truyền động

-

Ben2 Ben dập Ø80 x 50

-

Bạc đạnFBL / PBC

-

Xích RS60

-

Nút bấmChống bụi mốc siêu bền trên 5 năm (Idec - Japan)

Xi mạ thiết bị

-

Lô cánCrom

-

TyKen

-

Đòn gánhKen

Tiêu chuẩn ngoài

-

Độ bền & đồng đều máyCác thiết bị của máy được chế tạo hàng loạt từ các máy tiện, phay, mài, cắt CNC Nhật Bản và Robot hàn tự động đời mới, nhập mới 100% ABB - Thụy Sỹ, Yaskawa.

-

An toàn trong sử dụngMáy được lập trình tự động ngắt van khi xảy ra sự cố hư van hư công tắc giới hạn hành trình đảm bảo không bị phá hủy cơ cấu cơ khí hoặc bể phốt ben thủy lực, có nút khẩn cấp cả trước & sau để sử dụng xử lý.

-

Năng suất, chất lượng sản phẩmThiết kế chuẩn qua nhiều máy, phối hợp với tiêu chuẩn chất lượng giữa nhà chế tạo máy và khách hàng sử dụng máy, khảo sát thực tế tại các công trình đang sử dụng, nên đã có giải pháp tối ưu cho từng sản phẩm.

-

Đạt tiêu chuẩn về kỹ thuậtKiểm định, đánh giá chặt chẽ qua từng giai đoạn sản xuất máy, luôn cải tiến chất lượng.

-

Thiết kế theo yêu cầuĐây là sản phẩm chuẩn (Có thể thiết kế khi có yêu cầu riêng của khách hàng).

FINISHED PRODUCTS

Crimp Curving Machine - Vertical & Horizontal Other

Review

Do you have questions about this product? Do you want to complain or give feedback about a purchased order?

• Send information to Email info@saigonmachine.vn for immediate support.

• Contact Hotline (+84)932.000.999 | (+84)28.5425.7575 | (+84)28.5425.7979