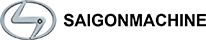

Single layer - Roll forming machine - Ribs roof trapezoidal

The main use of Single layer - Roll forming machine - Ribs roof trapezoidal is to change the metal structure, billet from flat steel plate to the corrugated iron shape desired by the operator, namely, ribs roof trapezoidal

Single layer - Roll forming machine - Ribs roof trapezoidal, roll forming corrugated iron sheets with a variety of designs and types, especially Saigon Machine - SGM specializes in making all kinds of corrugated iron forming machines to accurately shape the profile required by customers. Can be set to run in batches of multiple sizes.

Projects

ANG VANN - KHIM RATANA

Description

-

What conditions does SGM need to meet the Single layer - Roll forming machine - Ribs roof trapezoidal at Saigon Machine - SGM?

When designing a square wave corrugated iron rolling machine, technical staff must ensure the following criteria in order for the machine to operate smoothly and safely:

1. The machine must work for the highest efficiency and productivity, ensure the best roofing quality, the least waste.

2. The cold-rolled square corrugated iron rolling machine must have high rigidity and good gloss.

3. The number of waves on a commonly used corrugated iron sheet is: 09 Ribs roof trapezoidal or 11 Ribs roof trapezoidal (Depending on the needs of the customer, you can choose to add 5 Ribs roof trapezoidal, 6 Ribs roof trapezoidal,...)

4. Creating a corrugated iron shape that causes little error in shape and size, without tearing or breaking

5. The machine works stably: The quality of the finished product after rolling between the first and 1000th corrugated board is uniform (For bulk lamination)

-

Advantages of the machine:

1. The roof does not open the joints between the two panels when viewed from the bottom up, from the top down.

2. The machine is machined and assembled accurately to ensure parallelism between the axes and the cutter to ensure no aliasing when roofing.

3. Memory stores 10 orders to run automatically throughout the process.

4. Error between plates in a setting ± 1 mm.

5. Accumulated error when running from 1m-10m is not more than ±2mm.

6. Self-signaling tail cutting for the last order (Error ± 5 mm).

7. Store orders that have been running hour by day for months.

-

Operational features:

The corrugated ironing machine works on the principle of cold rolling, so when rolling, it has to go through certain steps.

Each step changes the shape of the corrugated iron a certain amount and the last step creates the shape of the product.

Therefore, the corrugated ironing machines are often arranged with many rolling shafts and each rolling shaft deforms the corrugated iron a certain amount to form the required corrugated iron.

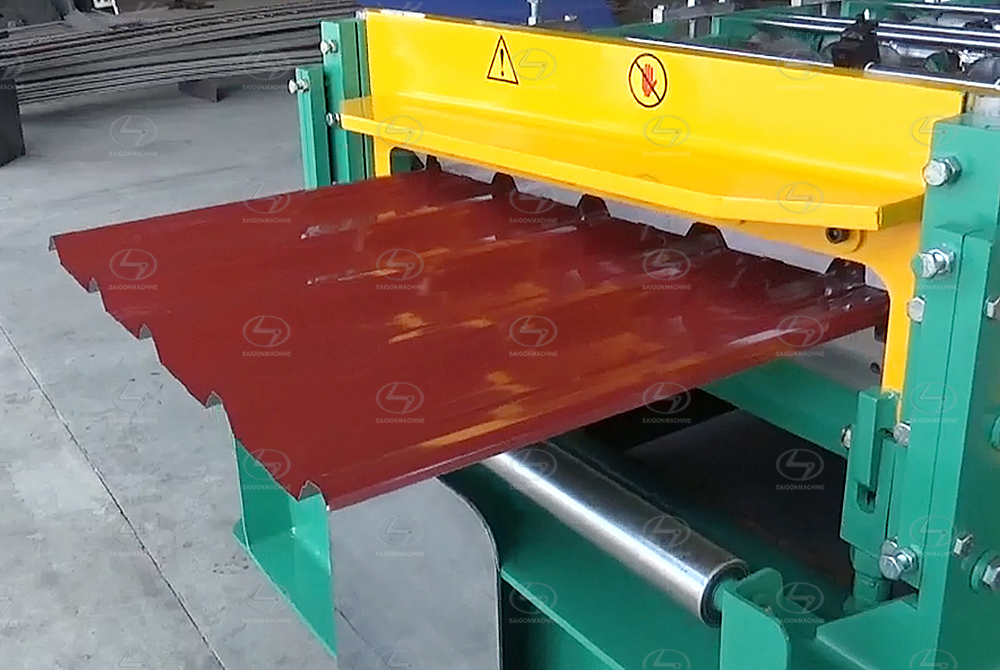

Profile

SPECIFICATIONS

Thông số máy

-

Kích thước (D x R x C)10500 mm x 1700 mm x 1400 mm

Chiều dài của máy có thể thay đổi ± (0.4 m ÷ 1.6 m) theo biên dạng sóng (Số cặp trục tăng giảm) -

Trọng lượng (Kg)8000 Kg ~ 9000 Kg

(Trọng lượng máy có thể thay đổi tùy theo biên dạng và số cặp trục) -

Năng suất / tốc độ (m/p)18 m/p ÷ 22 m/p

(Hoặc nhanh hơn tùy theo yêu cầu) -

Khung máyI#396

-

Vách máy (mm)20 mm

-

Thớt dao cắtThép Q345 cường độ cao dày 36 mm => 40 mm chống rung, cong, đảm bảo cho dao cắt không bị cong vênh trầy xướt trong quá trình sử dụng

-

Đường kính trục cán (mm)Ø70 mm

-

Công suất điện (KW / HP)5.5 KW / 7.5 HP

Số cặp trục

(Số lượng cặp trục tùy thuộc vào biên dạng)

-

05 sóng vuông18 Cặp - 20 Cặp

-

06 sóng vuông18 Cặp - 20 Cặp

-

07 sóng vuông22 Cặp

-

09 sóng vuông22 Cặp

-

11 sóng vuông22 Cặp

Thông số nguyên liệu

-

Độ dày (mm)0.25 mm ÷ 0.6 mm

-

Chiều rộng khổ tôn (mm)1200 mm

-

Độ cứngG300 - G550

Thủy lực

-

Motor điện (HP)7.5 HP

-

Đầu bơm (Cm³/v)31 Cm³/v

-

VanVan 2 cấp tốc độ

-

Giải nhiệt (Quạt)AH1012 (120 l/p)

-

Ống dầuYokohama / Dynesflex

-

Motor truyền động (cc/v)BM3 - 400 cc/v

-

Đồng hồ áp (Kg/cm²)250 Kg/cm² (Nhật Bản)

-

Dầu thủy lực R32 (Nhập khẩu)150L

Tủ điện điều khiển

-

CB nguồnFuji - Mitsu

-

Rơlay chống quá tải bảo vệ động cơCó

-

Bo nguồnOmron 24VDC

-

Bộ điều khiển công nghiệp (PLC)Mitsubishi - Japan

-

Màn hình7 Inch - Weintek - Đài Loan

-

Rơlay đóng ngắt van thủy lựcTiếp điểm đóng ngắt siêu bền chịu tải 10A - Idec - Izumi - Nhật Bản

-

Bo tỷ lệ điều khiển tốc độKhông

-

Tủ điều khiểnTủ treo tiết kiệm không gian

-

Bộ đếmOmron/ Autonics (360 Xung / Vòng)

-

Còi báo250VAC

-

Đèn báo250VAC

-

Dây điệnViệt Nam

Linh kiện

-

Dao cắt phẳngØ80 x 150 ST

-

Dao cắt hìnhØ80 x 150 ST

-

Xích RS80

-

Nút bấmChống bụi mốc siêu bền trên 5 năm (Idec - Japan)

-

Dao cắtThép chuyên dùng của Nhật Bản / Đức, dao cắt bền trên 5 năm. (Dùng đúng kỹ thuật bảo trì bảo dưỡng theo sự hướng dẫn của nhà cung cấp)

Xi mạ thiết bị

-

Lô cánCrom

-

Cần tủ điệnSơn

-

Ống canh cán (Ø88 - Ø112)Sơn

-

Ống canh lô (Ø76)Sơn

-

TySơn

-

Đòn gánhSơn

-

Ống lăn trước / sauMạ kẽm

-

Mặt nạ trướcMạ kẽm

-

Phần bao che xíchThép sơn màu

Tiêu chuẩn ngoài

-

Độ bền & đồng đều máyCác thiết bị của máy được chế tạo hàng loạt từ các máy tiện, phay, mài, cắt CNC Nhật Bản và Robot hàn tự động đời mới, nhập mới 100% ABB - Thụy Sỹ, Yaskawa.

-

An toàn trong sử dụngMáy được lập trình tự động ngắt van khi xảy ra sự cố hư van hư công tắc giới hạn hành trình đảm bảo không bị phá hủy cơ cấu cơ khí hoặc bể phốt ben thủy lực, có nút khẩn cấp cả trước & sau để sử dụng xử lý.

-

Năng suất, chất lượng sản phẩmThiết kế chuẩn qua nhiều máy, phối hợp với tiêu chuẩn chất lượng giữa nhà chế tạo máy và khách hàng sử dụng máy, khảo sát thực tế tại các công trình đang sử dụng, nên đã có giải pháp tối ưu cho từng sản phẩm, các đường cán sắc nét không bị trầy xướt, vết đen khi cán tôn lạnh như những sản phẩm của nhà cung cấp khác.

-

Đạt tiêu chuẩn về kỹ thuậtKiểm định, đánh giá chặt chẽ qua từng giai đoạn sản xuất máy, luôn cải tiến chất lượng.

-

Thiết kế theo yêu cầuĐây là sản phẩm chuẩn (Có thể thiết kế khi có yêu cầu riêng của khách hàng)

Single Layer - Roll Forming Machine Other

Review

Do you have questions about this product? Do you want to complain or give feedback about a purchased order?

• Send information to Email info@saigonmachine.vn for immediate support.

• Contact Hotline (+84)932.000.999 | (+84)28.5425.7575 | (+84)28.5425.7979