Lockseam | Seamlock - Roll Forming Machine

Please click on the button "+ READ MORE" so we can help you learn the concept of Lockseam corrugated iron | Seamlock (Origin, specifications, classification, advantages/disadvantages). Hope the information below will help you choose the right corrugated ironing machine.

1. Origin of roofing sheet:

Roofing corrugated iron is a product that has been present on the Vietnamese market for over 20 years. The sheet is made from thin-rolled steel, cold-rolled into a wave shape for the purpose of increasing hardness and drainage.

The purpose is to make cover panels for industrial and civil works. Roofing sheet is a substitute product for FIBRO Cement panels and is widely used in large-sized industrial projects where FIBRO Cement panels do not meet the load and size requirements.

The advantage of corrugated iron is that it is light and can be produced with any length up to over 100m.

☞ VIEW MORE: TÔN LOCKSEAM | SEAMLOCK LÀ GÌ?

2. What is roofing corrugated iron Lockseam | Seamlock?

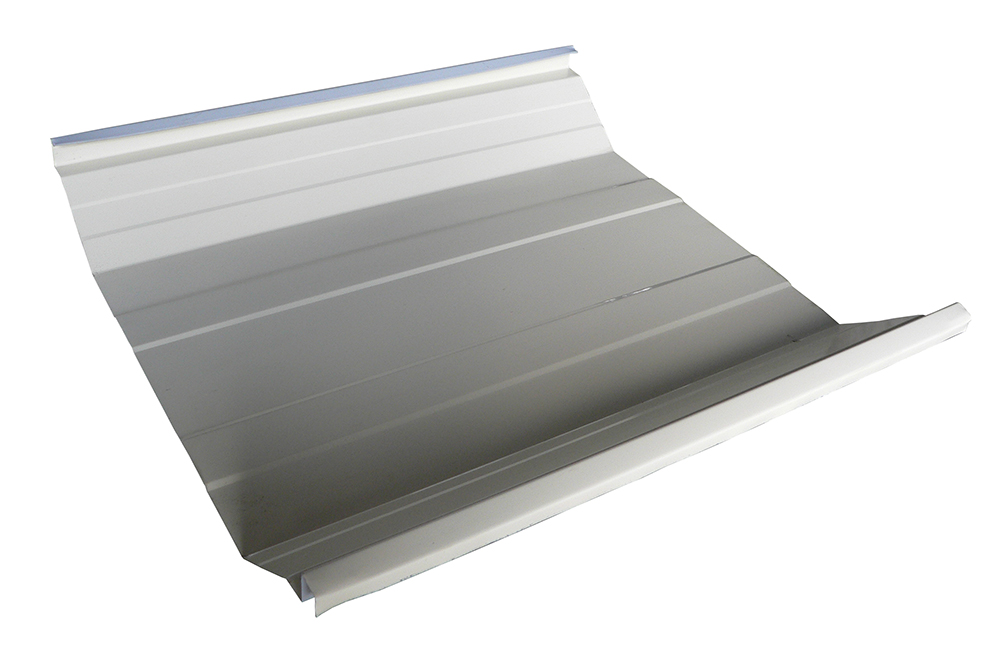

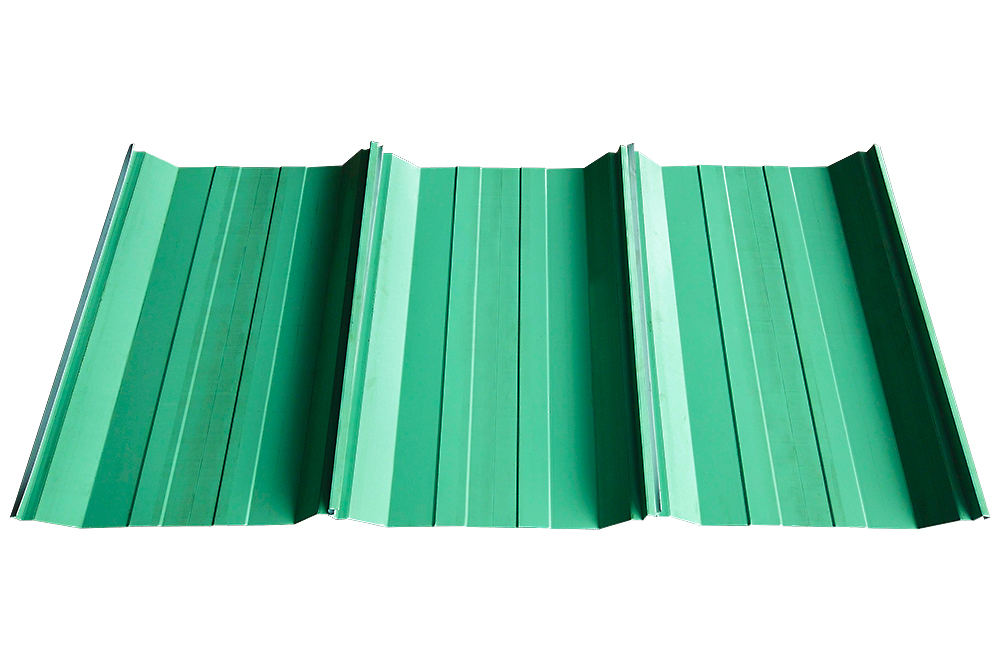

Details connecting corrugated iron with purlins are clamps. The clamp is screwed down to the purlin and is connected to the clamp by the edge banding principle.

Ton Lockseam | Seamlock is a newly manufactured corrugated iron, which has the same advantages as collapsible corrugated iron in that there is no hole in the sheet and overcomes the disadvantage of deformation of the supporting structure. This type can be suitable for factory projects with large apertures (over 100m).

In addition, the type of edge connection helps the edges of the corrugated iron sheet to better bond together and prevent water from passing through the corrugated iron connection points. However, the disadvantage of this type is that the connection is complicated and requires specific construction technology. The material used for this type is usually G300-G340 with high ductility.

3. Specifications:

Because it is made of steel, corrugated iron has the characteristics of the material such as high tensile strength, elasticity, and flexibility.

However, the disadvantage is poor corrosion resistance. Therefore, to achieve the purpose of use and increase durability, the corrugated board manufacturer has added plating layers to the surface to reduce the possibility of corrosion by the environment.

The usual plating layer is the zinc coating, anti-corrosion coating and color coating to create color for the material. As a result, the life of the corrugated iron sheet can last from 5 years to 50 years depending on the product thickness and plating.

Currently on the market there are many corrugated iron products from many different manufacturers, including some large enterprises such as Bluescope, Lotus, Southern SSSC, Nam Kim, Poshaco,Sunco…With a wide range of products diverse products. However, Vietnam does not have a factory producing corrugated iron sheets, so the source of raw materials is mainly imported from abroad such as Japan, Korea, and China. Enterprises in Vietnam mainly import corrugated iron coils from abroad and process thin, plated and rolled corrugated iron sheets.

4. The main classification of corrugated iron on the market today can be divided as follows:

Based on material properties can be classified according to strength and ductility. According to Japan's JIS standard, the products have the following types: G300, G340, G400, G440, G490, G540

Based on the protective coating, there are 2 main types: zinc plated (Z) and aluminum zinc plated (AZ).

The current corrugated iron products are very diverse, often classified according to the way of bonding and number of waves and wave height.

Single layer - Roll forming machine - Lockseam | Seamlock roof

Single layer - Roll forming machine - Lockseam | Seamlock roof, with specially designed rolling mill and cutter die for excellent profile. Lockseam | Seamlock solution connected corrugated board - Seam corrugated iron panels with profiled corrugated iron, connecting thin edges are designed to meet all architectural requirements.

With a buckle design that bends, tapers and seals, allowing the screw to be concealed underneath the corrugated iron - an innovation that meets aesthetics, versatility and efficiency.